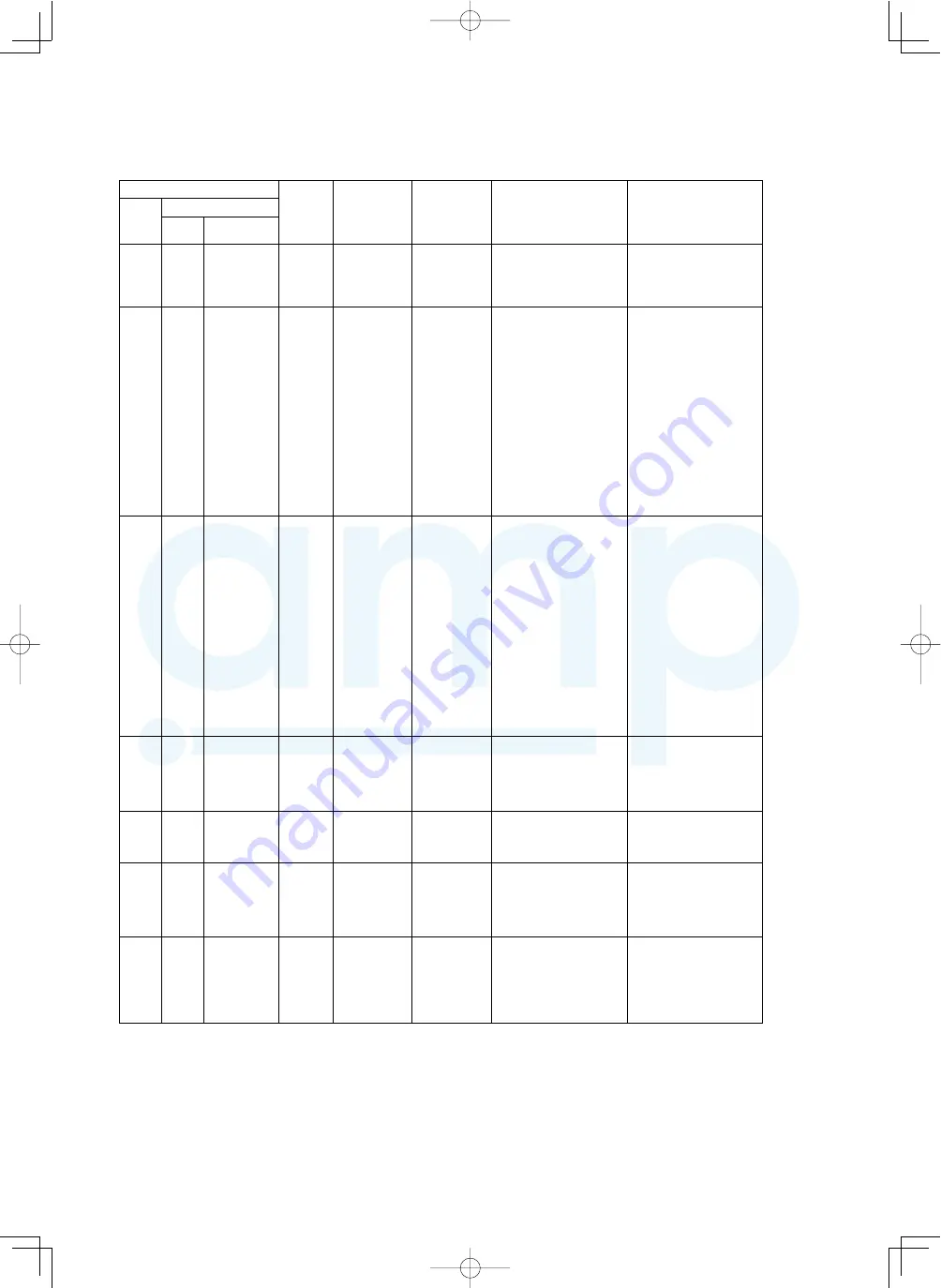

122

H03

H03

–

IPDU

Current

detection circuit

trouble

All stop

Current flow of at least

specified magnitude is

detected despite inverter

compressor having been shut

turned off.

Check current detection

circuit wiring.

Check trouble in outdoor

P.C. board (A3-IPDU).

H04

H04

–

I/F

Compressor

case thermostat

operation

All stop

Compressor case thermostat

performed protective

operation.

Check compressor case

thermostat circuit.

(Connector, wiring, P.C.

board)

Check full opening of

service valve.

(Gas and liquid side)

Check outdoor PMV

clogging.

Check SV4 circuit leakage.

Check miswiring /

misinstallation of SV4.

Check valve open status of

indoor PMV.

Check 4-way valve trouble.

Check refrigerant amount

shortage.

H06

H06

–

I/F

Activation of

low-pressure

protection

All stop

Low-pressure PS sensor

detects operating pressure

lower than 0.02 MPa.

Check service valves to

confirm full opening

(both gas and liquid sides).

Check outdoor PMV for

clogging.

Check for trouble in SV2 or

SV4 circuits.

Check for defect in low-

pressure PS sensor.

Check indoor filter for

clogging.

Check valve opening

status of indoor PMV.

Check refrigerant piping for

clogging.

Check operation of outdoor

fan (during heating).

Check for insufficiency in

refrigerant quantity.

L03

–

–

Indoor

unit

Duplicated

indoor outdoor

unit

Stop of

corresponding

unit

There is more than one

outdoor unit in group.

Check indoor addresses.

Check for any change

made to remote controller

connection (group /

individual) since indoor

address setting.

L04

L04

–

I/F

Duplicated

outdoor line

address

All stop

There is duplication in line

address setting for outdoor

units belonging to different

refrigerant piping systems.

Check line addresses.

L05

–

–

I/F

Duplicated

priority indoor

unit (as

displayed on

priority indoor

unit)

All stop

More than one indoor unit

has been set up as priority

indoor unit.

Check display on priority

indoor unit.

L06

L06

No. of priority

indoor units

I/F

Duplicated

priority indoor

unit (as

displayed on

indoor unit other

than priority

indoor unit)

All stop

More than one indoor unit

have been set up as priority

indoor unit.

Check displays on priority

indoor unit and outdoor

unit.

Location

of

detection

Description

System status

Check code detection

condition(s)

Check items (locations)

Main

remote

controller

Outdoor 7-segment display

Check

code

Sub-code

Check code

Check SV5 leak.

111

A10-1510.indb 111

A10-1510.indb 111

2016/04/08 17:21:08

2016/04/08 17:21:08

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk