123

L07

–

–

Indoor

unit

Connection of

group control

cable to stand-

alone indoor unit

Stop of

corresponding

unit

There is at least one stand-

alone indoor unit to which

group control cable is

connected.

Check indoor addresses.

L08

L08

–

Indoor

unit

Indoor group /

addresses not

set

Stop of

corresponding

unit

Address setting has not been

performed for indoor units.

Check indoor addresses.

Note:

This code is displayed

when power is turned on

for the first time after

installation.

L09

–

–

Indoor

unit

Indoor capacity

not set

Stop of

corresponding

unit

Capacity setting has not been

performed for indoor unit.

Set indoor capacity. (DN =

11)

L10

L10

–

I/F

Outdoor

capacity not set

All stop

Jumper wire provided on P.C.

board for servicing I/F P.C.

board has not been removed

as required for given model.

Check model setting of P.C.

board for servicing outdoor

I/F P.C. board.

L20

–

–

AI-NET

Indoor

unit

Duplicated

central control

address

All stop

There is duplication in central

control address setting.

Check central control

addresses.

Check network adaptor

P.C. board.

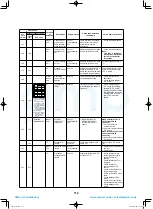

9

2

L

9

2

L

I/F

Trouble in No. of

IPDUs

All stop

Insufficient number of IPDUs

are detected when power is

turned on.

Check model setting of

P.C. board for servicing

outdoor I/F P.C. board.

Check connection of UART

communication connector.

Check A3-IPDU, fan IPDU,

and I/F P.C. board for

defect.

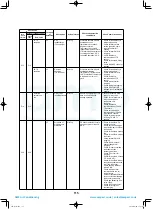

L30

L30

Detected

indoor address

Indoor

unit

External

interlock of

indoor unit

Stop of

corresponding

unit

Signal is present at

external error input

terminal (CN80) for 1

minute.

When external device is

connected to CN80

connector:

1) Check for defect in

external device.

2) Check for trouble in indoor

P.C. board.

When external device is not

connected to CN80

connector:

1) Check for trouble in indoor

P.C. board.

–

L31

–

I/F

Extended IC

trouble

Continued

operation

There is part failure in P.C.

board (I/F).

Check outdoor P.C. board

(I/F).

P01

–

–

Indoor

unit

Indoor fan motor

trouble

Stop of

corresponding

unit

Check the lock of fan motor

(AC fan).

Check wiring.

P03

P03

–

I/F

Discharge

temperature TD

trouble

All stop

Discharge temperature (TD)

exceeds 115 °C.

Check outdoor service

valves (gas side, liquid

side) to confirm full

opening.

Check outdoor PMV for

clogging.

Check resistance

characteristics of TD

sensor.

Check for insufficiency in

refrigerant quantity.

Check for trouble in 4-way

valve.

Check leakage of SV4

circuit.

Check SV4 circuit (wiring

orinstallation trouble in SV4).

Location

of

detection

Description

System status

Check code detection

condition(s)

Check items (locations)

Main

remote

controller

Outdoor 7-segment display

Check

code

Sub-code

(*) Concerning the “00” auxiliary

code

1) The wrong model setting

for the interface P.C. board

was used when the board

was replaced with the service

P.C. board.

may be displayed.

In such a case, the sub-codes

“08” to “0F” for L29, which are

not included in the table above,

2) The wrong model setting for

the fan IPDU P.C. board was

used when the board was

replaced with the service

P.C. board.

Check code

O

Fan IPDU

02

O

03

O

O

04

O

05

O

O

06

O

O

07

O

O

O

01

1

(Upper)

2

(Lower)

A3-

IPDU

Circle (O): Troubled IPDU

Check leakage of SV5

circuit.

112

A10-1510.indb 112

A10-1510.indb 112

2016/04/08 17:21:09

2016/04/08 17:21:09

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk