33

8-3. Functions at test operation

Checking COOL / HEAT test operation

The COOL / HEAT test operation can be performed using the indoor remote controller or outdoor interface circuit

board.

◆

Starting and stopping test operation

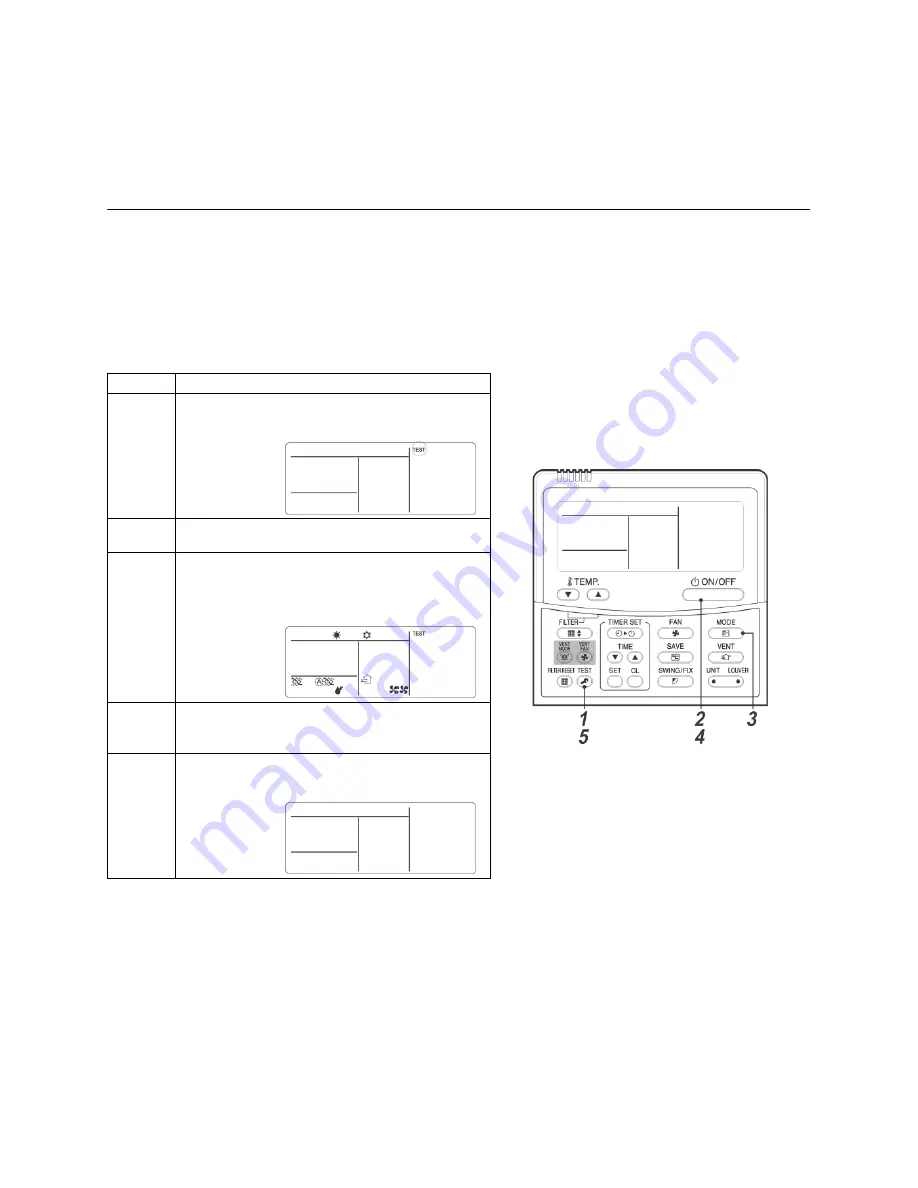

Performing test operation from the indoor remote controller

▼

Wired remote controller

Note:

The test operation ends in 60 minutes and the normal operation restarts.

* To check the ventilation mode switch, follow the procedure below:

(1) Perform Steps

1

and

2

in the above "Starting and stopping test operation".

(2) Press the "MODE" button to select [FAN].

(3) Press the "VENT MODE" button to select [Heat exchange] or [Automatic].

• The heat exchange is always performed when [Heat exchange] is selected.

• The bypass is always performed when [Automatic] is selected.

(4) Perform Steps

4

and

5

in the above "Starting and stopping test operation" to release the test operating mode.

Procedure

Operation

1

When the “TEST” button is pressed for 4 seconds or longer,

“TEST” appears in the display section, and the unit enters the

test operating mode.

2

Press the "ON / OFF" button.

3

Press the "MODE" button to select [COOL] or [HEAT].

• The heat exchange is always performed regardless of the

ventilation mode.

• The temperature cannot be adjusted during test operation.

• Errors are detected as usual.

4

When the test operation has been complete, press the "ON /

OFF" button to stop operation.

(The display in the display section is the same as in Step

1

.

5

Press the "TEST" button to release the test operating mode.

(“TEST” disappears from the display section, and the unit

returns to normal stop status.)

Summary of Contents for MD-VNK802HEXE

Page 120: ...118 11Owner s Manual Excerpt ...

Page 137: ...135 12Installation Manual Excerpt ...