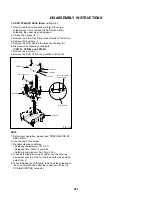

DISASSEMBLY INSTRUCTIONS

B2-2

NOTE

1.

2.

3.

4.

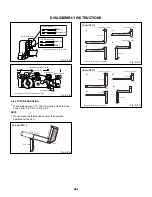

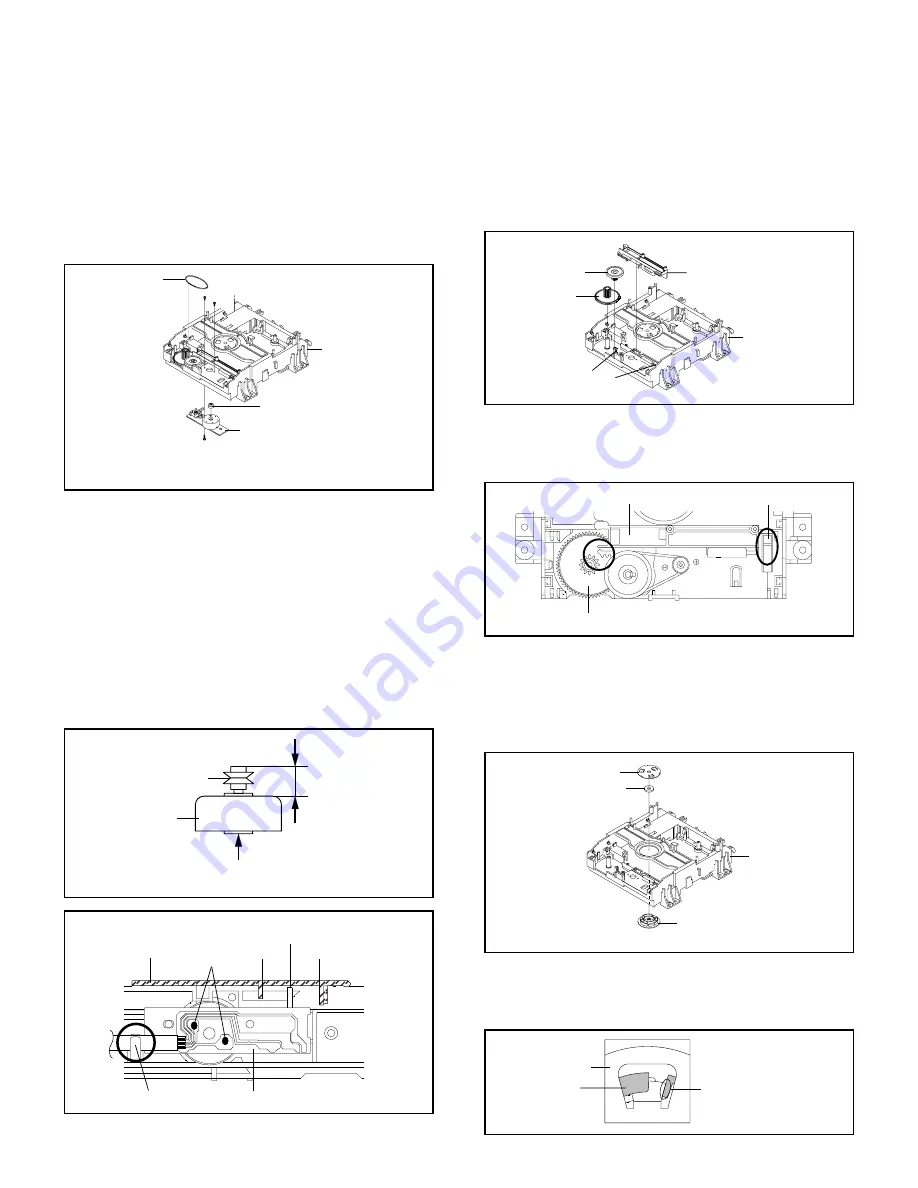

In case of the Pulley Motor installation, check if the value

of the Fig. 2-3-B is correct.

When installing the Loading Motor, do it on the position of

Fig. 2-3-C with the following soldering conditions.

Manual soldering conditions

• Soldering temperature: 350

±

5˚C

• Soldering time: Within 4 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When installing the Loading Motor PCB Ass'y, install it

correctly as Fig. 2-3-C.

In case of the Loading Motor PCB Ass'y installation, hook

the wire on the Traverse Ass'y as shown Fig. 2-3-C.

Fig. 2-3-B

7.0

±

0.1mm

Safety surface for pressing

of the insert.

Loading Motor

Pulley Motor

Fig. 2-3-C

Rack Loading

A

B

The Lever should be position

between A and B.

Check Hook

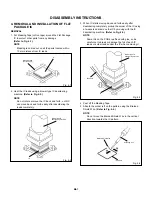

2-4: RACK LOADING/GEAR MAIN/GEAR PULLEY

(Refer to Fig. 2-4-A)

1.

2.

3.

Press down the catcher

1

and slide the Rack Loading.

Unlock the support

2

and remove the Gear Pulley.

Remove the Gear Main.

Loading Motor PCB Ass’y

Loading Belt

Pulley Motor

1

Loader Sub Ass’y

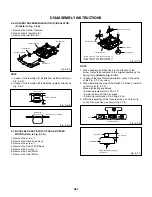

2-3: LOADING MOTOR PCB ASS'Y/ LOADING BELT

(Refer to Fig. 2-3-A)

1.

2.

3.

4.

5.

Remove the Loading Belt.

Remove the screw

1

.

Remove the 2 screws

2

.

Remove the Loading Motor PCB Ass'y.

Remove the Pulley Motor.

Fig. 2-3-A

2

2

Loading Motor PCB Ass’y

• Screw Torque: 2.5

±

0.3kgf•cm (Screw

1

)

• Screw Torque: 1.0

±

0.3kgf•cm (Screw

2

)

Rack Loading

1

Main Frame

Gear Main

Gear Pulley

2

Fig. 2-4-A

Fig. 2-4-B

NOTE

1. In case of the Rack Loading installation, do not mesh it

to the Gear Main as shown the Fig. 2-4-B.

Check Hook

Gear Main

Rack Loading

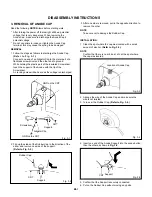

2-5: CLAMPER ASS'Y (Refer to Fig. 2-5-A)

Press the Clamper and rotate the Plate Clamper

clockwise, then unlock the 3 supports

1

.

Remove the Clamper Plate, Magnet Clamper and

Clamper.

1.

2.

Plate Clamper

Magnet Clamper

Fig. 2-5-A

Main Frame

Clamper

1

1

1

NOTE

1. In case of the Clamper Ass'y installation, install correctly

as Fig. 2-5-B.

Fig. 2-5-B

No gap

Plate Clamper

Clamper

Soldering