100

2. Clearing from the interface P.C. board

Using the switches on the interface P.C. board, this function is to clear the currently detected error for each

refrigerant circuit system without resetting the power supply.

(

→

Restart of error detection)

Errors in both outdoor and indoor units are once cleared.

3. Clearing of error check code by power reset

This function is provided to clear error in a refrigerant circuit system by resetting the power of all the outdoor

and the indoor units.

(

→

Restart of error detection)

As same as the clearing method on the interface P.C. board, errors of both the outdoor and the indoor units

are once cleared.

Method

Be sure to reset power of both the outdoor and the indoor units.

NOTE) After power reset, it requires usually 3 minutes to power-on due to the initial communication of the

system. In same cases, it requires Max. 10 minutes.

Set the rotary switches on the interface P.C. board of the

outdoor unit to the following setting.

SW01=[2] SW02=[16] SW03=[1]

(7-segment display)

[A]

[ E ]

[B]

[ C L ]

Push the push-switch SW04 on the interface P.C. board of

the outdoor unit for 5 seconds or more.

[ C L] is displayed in 7-segment display [B] on the P.C. board

(for 5 seconds), and the error is completely cleared.

(7-segment display)

[A]

[ E ]

[B]

[ ]

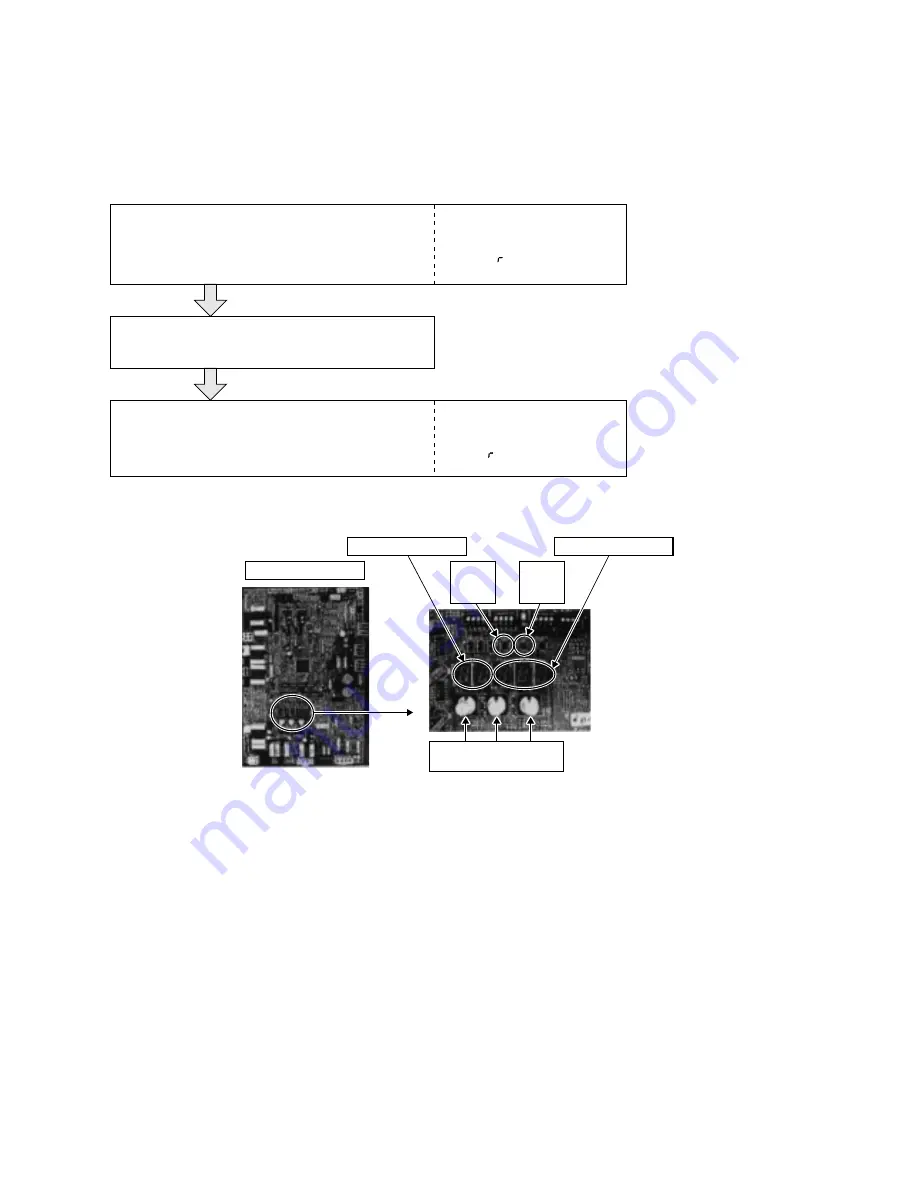

Interface P.C. board

7-segment display [A]

7-segment display [B]

Push

switch

SW04

Push

switch

SW05

SW01 SW02 SW03

<Rotary switch>