183

Method 2

Before exchange, it is impossible to read out the setup contents due to EEPROM error.

Exchange of P.C. board for service & power ON: Procedure 2

ò

Writing-in of the setup data such as the model name, capacity code, indoor unit address high ceiling setup,

connection setup of option,

etc to EEPROM based upon customer’s information: Procedure 3

ò

Power supply reset (All the indoor units connected to the remote controller in case of group operation control)

Procedure 1 : Readout setup contents from EEPROM

(Contents of EEPROM with setup changed at local site include setup at shipment from the factory are read out.)

1. Push

SET

+

CL

+

TEST

buttons simultaneously for 4 seconds or more.

1

(Corresponds to number of the operation diagram of the remote controller.)

∗

In a group operation control, the firstly displayed unit No. indicates the header indoor unit No.

In this case,

is displayed in the item code (DN). The fan of the selected indoor unit operates, and also

starts swinging in a model with flap.

2. Every pushing

UNIT

, the indoor unit Nos. in the group control are displayed successively.

2

(Corresponds to number of the operation diagram of the remote controller.)

Specify the indoor unit No. to be exchanged.

∗

The fan of the selected indoor unit operates, and also starts swinging in a model with flap.

3. Using temperature setup

/

buttons, the item code (DN) can be moved up/down one by one.

3

(Corresponds to number of the operation diagram of the remote controller.)

4. First change the item code (DN) from

→

. (Setup of filter sign lighting time)

In this time, make a note of contents of the displayed setup data.

5. In the next time, change the item code (DN) using

/

buttons.

Make a note of contents of the setup data as same as the above.

6. Then repeat item 5., and make a note of contents of the important setup data as indicated in the attached

table (Example).

∗

The item code (DN) is consisted with

to

))

.

DN No. may jump on the way.

7. When noting has finished, push

TEST

button to

return to the normal stop status.

6

(Corresponds to number of the operation diagram

of the remote controller.)

(It requires approx. 1 minute to operate the remote

controller.)

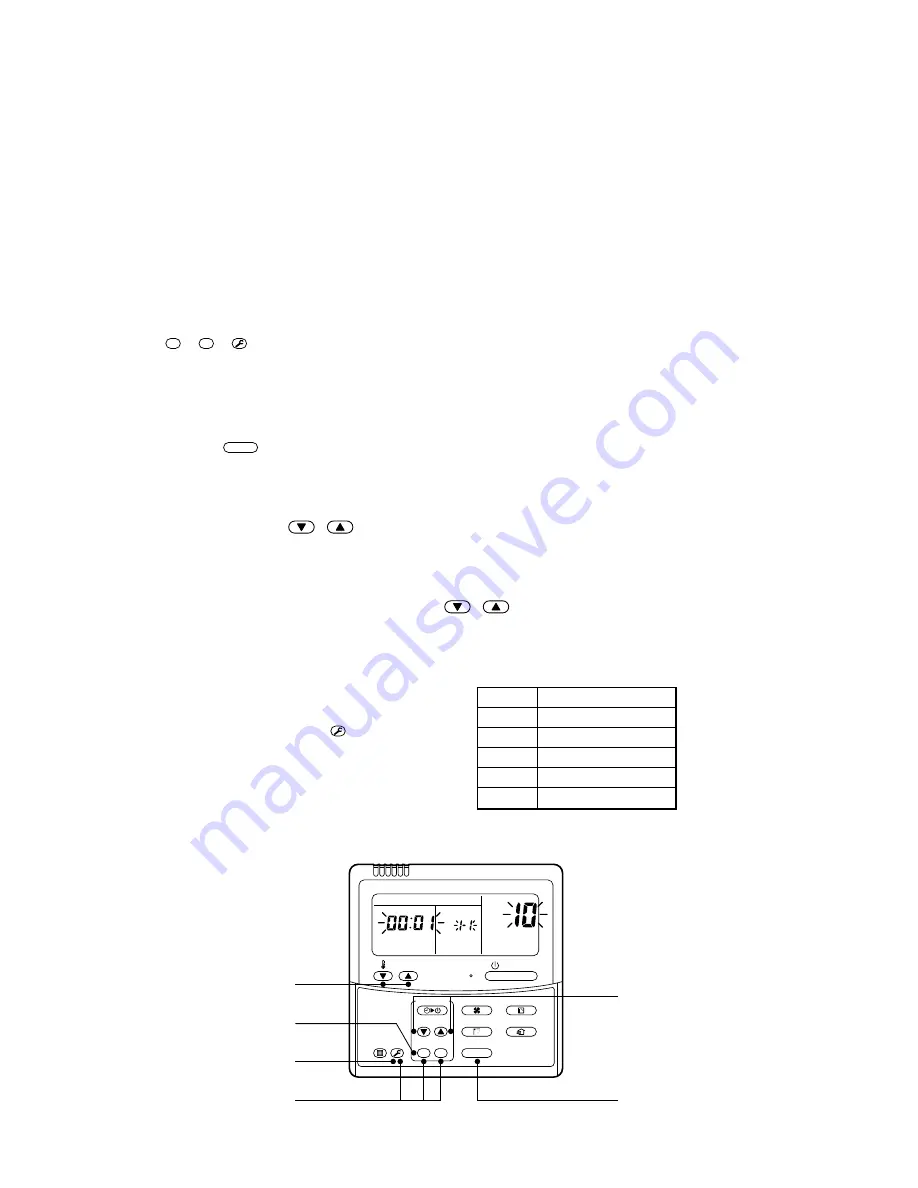

<Remote controller operation diagram>

3

6

1

5

2

4

ON / OFF

FAN

TEMP.

SWING/FIX

TIME

MODE

VENT

UNIT

SET

CL

FILTER

RESET TEST

TIMER SET

UNIT No.

DATA

SET

R.C.

No.

DN

10

11

12

13

14

Contents

Type

Indoor unit capacity

Line address

Indoor address

Group address

Type and capacity of

the indoor unit are

necessary to set up

the revolution

frequency of the fan.

Item code necessary at minimum