79

9. TEST OPERATION

9-1. Procedure and Summary of Test Operation

A test operation is executed in the following procedure. When a trouble or an error occurs in each step, remove

causes of a trouble or an error referring to the section “9. Troubleshooting”.

Check the basic items, mainly the installation work.

Be sure to enter the check results in the check list 1 and 2.

It is the check after the power has been turned on.

Check the refrigerant circuit system is normally turned on.

Start the address setup in the outdoor/indoor units.

(NOTE) The operation does not start by only power-ON.

Carry out a test operation.

Check air blowing and cooling/heating operation in the indoor unit.

Check before test operation

Set up the addresses.

Test operation

END

Check the main power supply

is turned on.

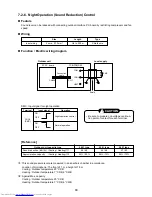

9-2. Check Items before Test Operation

Prior to the test operation, check the following items so that there is no trouble in the installation work.

Main check items for electric wiring

The communication system differs from

that of R22 or R407 refrigerant

“Modular Multi system”

air conditioner.

Check again cautious points on wiring.

1. In case that a center control

system is not connected:

Note)

The above figure does not show all the electric cables.

For details, refer to the installation manuals for outdoor unit, indoor unit, remote controller, or optional devices.

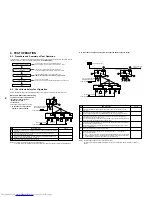

2. In case that a central control system is connected (Before address setup)

Note)

The above figure does not show all the electric cables.

For details, refer to the installation manuals for outdoor unit, indoor unit, remote controller, or optional

devices.

No.

Main check items

Are indoor and outdoor communication lines of the outdoor unit connected to U1/U2

terminals?

Is the relay connector between U1/U2 terminal and U3/U4 terminal removed?

(Set up at shipment from the factory)

Is the terminator resistor (SW30-2) on the interface P.C. board of the outdoor unit

turned on? (Set up at shipment from the factory)

Is the end terminal of the shield cable grounded?

Check

Outdoor unit

U1 U2

U3 U4

E

N

L

3

A

B

U1 U2

E

N

L

2

4

1

A

B

U1 U2

E

N

L

Indoor unit

Earth leakage breaker

Power supply

Power supply

Over current breaker (fuse)

Earth leakage breaker

Remote

controller

A

B

U1 U2

E

N

L

Outdoor unit

U1 U2

U3 U4

E

N

L

3

4

3

4

U1 U2

U3 U4

A

B

U1 U2

E

N

L

2

5

1

1

5

A

B

U1 U2

E

N

L

Indoor unit

Earth leakage breaker

Power supply

Power supply

Over current breaker (fuse)

Earth leakage breaker

Central control units

Remote

controller

A

B

U1 U2

E

N

L

Other refrigerant system

Other refrigerant

system

U1 U2

U3 U4

E

N

L

2

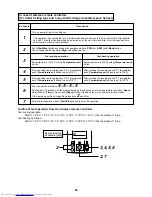

No.

Main check items

Are indoor and outdoor communication lines of the outdoor unit connected to U1/U2

terminals?

Is the relay connector between U1/U2 terminal and U3/U4 terminal removed?

(Set up at shipment from the factory) (Before address setup, remove the relay connector.)

Is the communication line of the central control system connected to the outdoor unit

U3/U4 terminals of each refrigerant line?

(The communication line of the central control system may be connected to the communi-

cation lines of the indoor/outdoor communication lines.)

Is the terminal resistance (SW30-2) on the interface P.C. board of the outdoor unit turned on?

(Set up at shipment from the factory)

(After address setup, turn off SW30-2 of the outdoor unit except the smallest unit after

check of trial operation.)

Is the end terminal of the shield cable grounded?

When the refrigerant line and the central control system of the 1 : 1 air conditioner

(DI, SDI) are connected:

→

Are “1 : 1 model” connection interface (TCB-PCINTLE2) adaptors correctly connected?

→

When the digital inverter air conditioner operates with group operation, twin, operation,

are the adopters connected to the header unit of the indoor unit?

Check