– 26 –

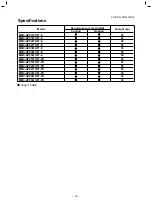

FILE NO. SVM-

16042

No.

10

Item

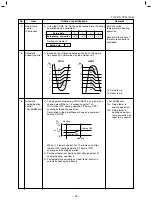

Recovery control

for heating

refrigerant (Oil)

Outline of specifications

The indoor unit which is under STOP/Thermo. OFF

status or which operates in [FAN] mode performs the

following controls when it received the heating

refrigerant (Oil) recovery signal from the outdoor unit.

1) Opens PMV of the indoor unit with a constant

opening degree.

2) Detects temperature of TC2 and then closes PMV.

3) Counts No. of recovery controls and operates the

indoor fan and the drain pump for approx. 1 minute

after finish of recovery control until the control

count reaches the specified count.

The direction of the louver becomes horizontal

direction.

Remarks

s

The indoor unit which is

under thermo. OFF (COOL)

status or which operates in

[FAN] mode stops the indoor

fan and displays [READY ].

s

Recovery operation is usually

performed every 1 hour.

Compensation

control for short

intermittent

operation

Drain pump

control

䈜

Option

Elimination of

retained heat

HA control

Display of filter

sign [

]

(Not provided to

the wireless type)

1) For 5 minutes after start of operation, the opera-

tion is forcedly continued even if the unit enters in

thermo. OFF condition.

2) However the thermostat is OFF giving prior to

COOL/HEAT selection, READY

for operation

and protective control.

1) Drain pump operates while in cooling operation.

(including DRY operation)

2) During operation of the drain pump, if the float

switch operates, the drain pump continuously

operates and a check code is illuminated.

3) During stop status of the drain pump, if the float

switch operates, the thermostat is forcedly off and

this control operates the drain pump. After

continuous operation of the float switch for approx.

5 minutes, this control stops the operation and a

check code is issued.

1) When the unit stopped from [HEAT] operation, the

indoor fan operates with [L] for approx. 30 seconds.

1) ON/OFF operation is available by input of HA

signal from the remote site when connected to

remote controller or the remote ON/OFF interface.

2) HA control outputs ON/OFF status to HA terminal.

3) The I/O specifications of HA conform to JEMA

standard.

1) The filter sign is displayed with LCD by sending

the filter-reset signal to the remote controller when

the specified time (2500H) elapsed as a result of

integration of the operation time of the indoor fan.

2) The integrated timer is cleared when the filter-reset

signal is received from the remote controller.

In this time, if the specified time elapsed, the

counted time is reset and the LC display is deleted.

Attached Drain pumpkit

(TCB-DP31CE)

Check Code [P10]

When using HA terminal

(CN61) for the remote ON/

OFF, a connector sold sepa-

rately is necessary.

In case of group operation, use

the connector to connect HA

terminal to either header or

follower indoor unit.

[

FILTER] goes on.

11

12

13

14

15

Filter time

2500H