3-170

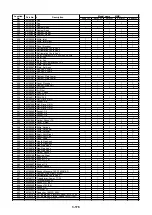

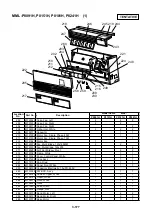

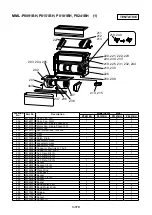

Model name MMD-

Location

No.

Part No.

Description

P0151H

P0181H

P0241H

P0361H

P0481H

401

43158166 Transformer, Power, ST-11227

1

1

1

1

402

43160427 Terminal, 5P

1

1

1

1

403

43160469 Terminal, Block, 6P

1

1

1

1

404

43160341 Terminal, Block, 4P

1

1

1

1

405

43155164 Capacitor

1

406

43155142 Capacitor, 4µFD, 450V

1

407

43155137 Capacitor

1

408

43155134 Capacitor, MF, EAG45M605UF1

1

409

43154141 Relay, LY2F-L, AC230V

1

1

1

1

410

43154135 Relay, LY3F-JT, AC230V

1

1

1

1

411

43150241 Sensor

1

1

1

1

412

43150200 Sensor, TA

1

1

1

1

413

43150223 Sensor

1

1

1

1

414

4316V046 P.C. Board Ass’y

1

1

1

1

415

43060700 Fuse, 10A, 250V

2

2

2

2

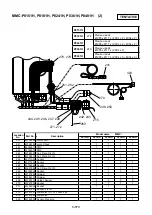

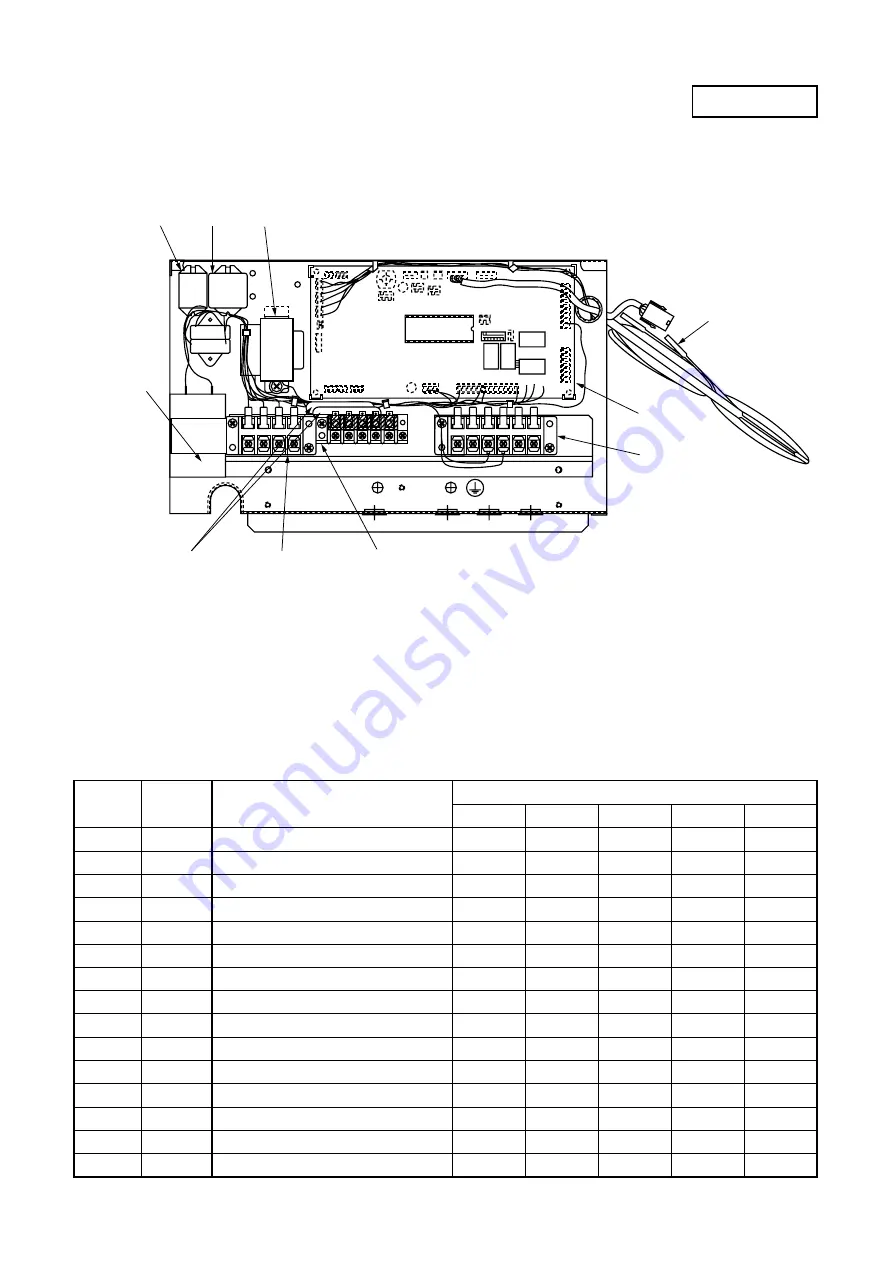

RC

(A)

43F1

R

S

1

2

11 12

F1 F2 F3 F4

A B C P Q

(A)

43F2

Tr

409

410

401

405

406

407

408

415

404

402

414

403

411

412

413

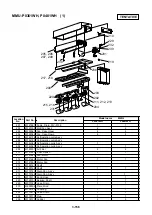

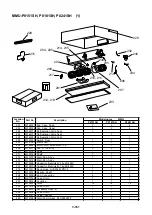

MMD-P0151H, P0181H, P0241H, P0361H, P0481H (2)

TENTATIVE