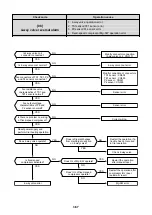

3-52

Check

code

Detected

position

Check code

name

Cause

(Position)

Trouble detection condition

Check item (Position)

d6

Interface TK3 sensor

alarm

Temp. sensor

(TK3) to

detect oil level

Sensor resistance value was

infinity or zero (Open, Short).

• Check connector connection of TK3

sensor.

• Check characteristics of TK3 sensor

resistance value.

• Check outdoor P.C. board (interface)

error.

d7

Interface Low oil level

detection

protection

Oil level

detection

circuit

Oil shortage status was

continuously detected for

approx. 2 hours while oil

equalizing control was

continuously executed.

<Check all outdoor units in the line.>

• Check the valve to remove oil in

compressor case.

• Check for blockage in oil separator and oil

return circuits.

• Check for blockage in balancing pipe

valve and pipe between outdoor units.

• Check misconnection of TK1, TK2, and

TK3.

• Check characteristics of TK2 sensor

resistance value.

• Check leakage of reducing valve (SV3A).

• Check leakage of pressurize valve

(SV3C).

• Check for blockage of oil return valve

(SV3B).

• Check peripheral circuits of oil tank.

1) Leakage of check valve

2) Blockage of capillary

• Check for substantial refrigerant

stagnation in compressor case.

1) Check leakage of cooling bypass circuit

(PMV3).

d8

Interface TK1 temp.

detection

circuit alarm

Oil level

detection

circuit

Temp. change at primary

side of oil tank was not

detected when oil level

detection control was

executed.

• Check out of place of TK1 pipe sensor.

• Check characteristics of TK1 sensor

resistance value.

• Check misconnection of TK1, TK2, and

TK3.

d9

Interface TK2 temp.

detection

circuit alarm

Oil level

detection

circuit

Temp. change at secondary

side of oil tank was not

detected when oil level

detection control was

executed.

• Check out of place of TK2 pipe sensor.

• Check characteristics of TK2 sensor

resistance value.

• Check peripheral circuits of oil tank.

1) Leakage of stop valve

2) Blockage of capillary

3) Blockage of strainer

4) Check contact of TK2 sensor circuit

with discharge pipe.

• Check misconnection of TK1, TK2, and

TK3.

dA

Inverter

Heat sink

overheating

alarm

IGBT

overheating

protection

Overheating of IGBT was

detected.

• Check IGBT error.

(IGBT built-in temp. sensor error)

• Check error of outdoor fan system.

• Check for blockage in cooling duct of heat

sink.

• Check mounting failure of IGBT heat sink.

db

Interface Oil level

detection

circuit

blockage

detection

Oil level

detection

circuit

Temp. change at primary and

secondary sides of oil tank

was not detected when oil

level detection control was

executed.

• Check for blockage of peripheral circuits of

pressurize valve (SV3C).

• Check connection of SV3C valve coil and

connector.

dC

Interface Oil level

detection

circuit

leakage

detection

Oil level

detection

circuit

The status that TK1 temp. is

high (50°C or more) was

continuously detected for a

long time.

• Check leakage of pressurize valve

(SV3C).

• Check characteristics of TK1 sensor

resistance value.

• Check operation out of use temp. range of

outdoor unit.

(Cooling overload operation, etc.)