3-90

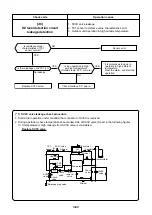

Check code

Operation cause

[d9]

TK2 temperature detection circuit alarm

1. TK2 sensor out of place, miswiring, resistance value

characteristics error

2. Oil tank peripheral circuit error

Check valve leakage

Capillary blockage

Strainer blockage

[ ]

YES

YES

YES

YES

YES

NO

NO

NO

NO

Leakage/blockage

Is TK2 sensor out of place?

Does TK2 sensor circuit

contact with discharge pipe?

Is there miswiring of

TK1/TK2/TK3 sensor?

Is resistance value characteristics

of TK2 sensor normal?

Is there leakage or blockage in

peripheral circuit of oil tank? (

*

1)

Check interface P.C. board.

[ ]

TK1 sensor : CN516

TK2 sensor : CN515

TK3 sensor : CN507

Correct pipe so that TK2 sensor

circuit does not contact with

discharge pipe.

Replace leaked/blockage part.

Sensor error

Modify miswiring.

Modify sensor mounting.

Accumulator

Balancing pipe valve

Oil

tank

SV3C valve

Check joint

Strainer

Strainer

Strainer

SV3A

valve

SV3B

valve

TK1

sensor

Check

valve

Check

valve

Check

valve

Capillary

Capillary

TK2

sensor

Oil

removal

valve

Compressor

Oil

separator

A

B

C

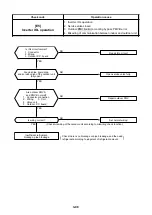

( * 1) Oil tank peripheral circuit leakage/blockage check procedure

1. After resetting power supply, start a trial operation.

2. Set SW01/SW02/SW03 on interface P.C. board to

1/16/1, respectively.

3. Check display on the 7 segment of interface P.C. board.

In case of judgment result “A0” “A1”

→

Oil level is adequate. Resume the operation.

In case of judgment result “A4”

→

Possibility of oil tank circuit leakage/blockage is considered

Check the following items.

4. Start a trial operation under condition that

AC220–240V, 50Hz (

AC220V, 60Hz

)

power is on to SV3C valve.

5. During operation, check whether discharge gas flows

to the strainer secondary side (A part in the right

figure) at downstream of TK2 sensor circuit, and

capillary secondary side (B part in the right figure).

→

If blocked part is found, replace the part.

6. During operation, check whether leakage occurs in

the check valve (Two positions) of pipe connecting

the oil tank and compressor case.

(Check temperature of C part in the right figure.)

→

If leakage is found, replace the part.

7 segment display

When operation has started

“OL” “– –”

During detection of oil level

“OL” “FF” or “Numeral”

Judgment result of oil level

“OL” “A0” “A1” or “A4”