11

5

REFRIGERANT PIPING

WARNING

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

• If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

• If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas

may generate.

REQUIREMENT

When the refrigerant pipe is long, set the support brackets to fix the pipe with 2.5 to 3m intervals.

If the pipe is not fixed, abnormal sound may generate.

Be sure to use the flare nuts attached to the indoor unit or those fro R410A.

Permissible pipe length and permissible height difference

They are different according to the used outdoor unit.

For details, refer to the Installation Manual attached to the outdoor unit.

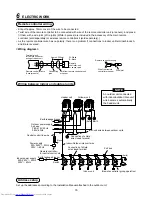

Piping material and dimensions

Piping material

Model MMD-AP

Pipe size (mm)

Gas side

Liquid side

Phosphor deoxidization joint-less pipe for air conditioner

0071BH to 0121BH

0151BH to 0181BH

0241BH to 0561BH

Ø9.5

Ø12.7

Ø15.9

Ø6.4

Ø6.4

Ø9.5

+0

- 0.4

A

• Use a clean and new pipe, and check that impurity such as dust, oil, moisture, etc. does not adhere in the pipe.

Pipe Forming/End Positioning

Flaring

1. Cut the pipe with a pipe cutter.

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools can be used by

adjusting projection margin of the copper pipe.

• Flaring diam. meter size : A (Unit : mm)

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

A

R410A

9.1

13.2

16.6

19.7

*

In case of flaring for R410A with the conventional

flare tool, pull it out approx. 0.5 mm more than that

for R22 to adjust to the specified flare size.

The copper pipe gauge is useful for adjusting

projection margin size.

90˚

Obliquity

Roughness

Warp