21

In case of wireless remote controller

Receiver unit

M4 × 25 screw

(2 pieces)

Small screw

Spacer

Notch

Nameplate

In case of abnormal test operation

• When the test operation has not normally finished, refer to the check No. and the check position in the

“9 TROUBLESHOOTING”.

• If the test operation has been executed before installation of the outside duct, a protective control works

resulted in stop of the air conditioner, and then an error code [P12] may be output. However it is not a trouble.

(The current limit control works in the characteristics of DC motor which is adopted in the indoor fan motor of this model.)

Carry out a test operation by setting the air volume tap to small or closing the discharge port before installation

of the outside duct.

• Be sure also to stop the fan in exchange of high-performance filter or opening of the service board.

After the test operation has finished, reset necessarily the leak breaker of the indoor unit.

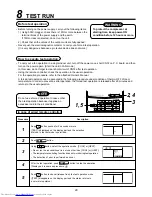

Procedure

1

2

3

4

Description

Remove a small screw which fixes the nameplate of the receiver unit.

Remove the nameplate of the sensor section by inserting a minus screwdriver, etc into the notch at the

bottom of the plate, and set the Dip switch to [TEST RUN ON].

Execute a test operation with

button on the wireless remote controller.

•

,

, and

LED flash during test operation.

• Under status of [TEST RUN ON], the temperature adjustment from the wireless remote controller is invalid.

Do not use this method in the operation other than test operation because the equipment is damaged.

Use either COOL or HEAT operation mode for a test operation.

* The outdoor unit does not operate approx. 3 minutes after power-ON and operation stop.

After the test operation finished, stop the air conditioner from the wireless remote controller, and return Dip

switch of the receiver section as before.

(A 60-minutes timer clearing function is attached to the receiver section in order to prevent a continuous test

operation.)