–

90

–

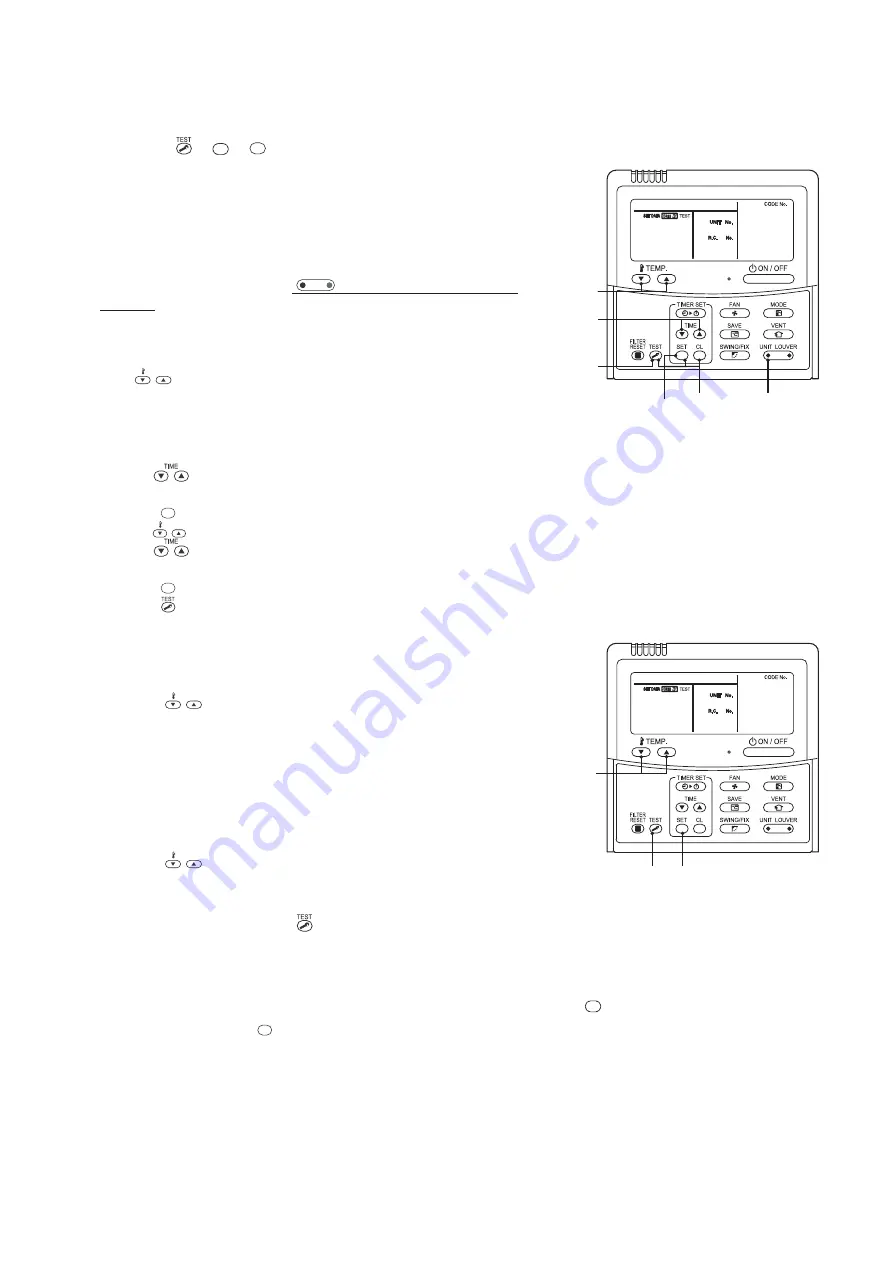

Procedure 3: writing setting data in EEPROM

(The EEPROM of the service P.C. board has been set to the factory default values.)

4

– (7)

1

4

– (3, 6)

4

– (1, 5)

3

2

00 04

3- 3

10

1

Push the +

SET

+

CL

buttons simultaneously and hold

for at least 4 seconds. (This number corresponds to

the same number shown on the Remote Controller

Operation Diagram.)

(Under UNIT No., ALL is displayed.)

At the same time, the CODE No. (DN code) 10 is displayed,

and the fan of the indoor unit comes on, with the louver swinging,

depending on the model.

2

Push the left part of the

UNIT LOUVER

button (left side of the

button) to display the indoor unit No. one by one in the

group control. Specify the indoor unit No. whose

service PC board was replaced.

(This operation is not available if the UNIT No. shows

ALL

ALL

ALL

ALL

ALL

.)

3

The

TEMP.

button allows you to moved the CODE No.

(DN code) up / down by one place.

4

First, set the type and capacity codes of the indoor unit.

<Fig. 1 RBC-AMT32E>

(Changing the type and capacity codes in EEPROM overwrites the factory default settings.)

(1) Set the CODE No. (DN code) to 10 (no change)

(2) Use the

button to select the type.

(For example, 0001 is for the 4-way cassette type.) - See the CODE No. list.

(3) Push the

SET

button. (The display should change from flashing to steady.)

(4) Use the

TEMP.

button to set the CODE No. (DN code) to 11.

(5) Use the

button to set the capacity code.

(For example, 0012 is for the 027 type.) - See the CODE No. list.

(6) Push the

SET

button. (The display should change from flashing to steady.)

(7) Push the button to bring the system back to normal off state.

<Fig. 1 RBC-AMT32E>

6, 8

10

5

00 04

3- 3

10

5

Next, write any setting changes made on-site after

installation, such as address settings, in the EEPROM.

Perform the tasks specified in step 1 again.

6

Use the

TEMP.

button to set the CODE No. (DN code) to

01 (To set filter sign lighting time)

7

Check the value displayed with the value jotted down in

Procedure 1 and information proved by the customer.

(1) If there is a discrepancy, change the setting in accordance with

the jotted-down value, and push the button.

(The display should change from flashing to steady.)

(2) If there is no discrepancy, do nothing.

8

Use the

TEMP.

button to change the CODE No. (DN code).

Again, check the value, and change the setting if necessary.

9

Repeat steps 6 and 7 until all the settings are checked.

10

When finished, push the button to bring the system back to normal off state.

In the case of group operation, turn the unit off, reconnect the indoor-indoor group control wiring and CN41

connectors, and turn on all the indoor units.

(It takes the system about 1 minute to become responsive to remote controller operation.)

* CODE No. (DN code) go from 01 to FF with a few gaps along the way.

If you realize you have wrongly corrected a certain setting after pushing the

SET

button, you can recover the

initial value by pushing the

CL

button, provided that the CODE No. (DN code) is yet to be changed.

Summary of Contents for MMD-AP0186HP-E

Page 20: ... 20 4 WIRING DIAGRAMS ...