– 10 –

1-1. S-MMS System Specifications to Connect Fresh Air Intake Indoor Unit

1-1-1. Combination Conditions

The fresh air intake indoor unit is connectable to S-MMS (Super Modular Multi system).

However this is not connectable to S-HRM (Super Heat Recovery Multi system).

[Installation example

of all fresh air intake indoor unit system]

[Installation example

of intermingled system]

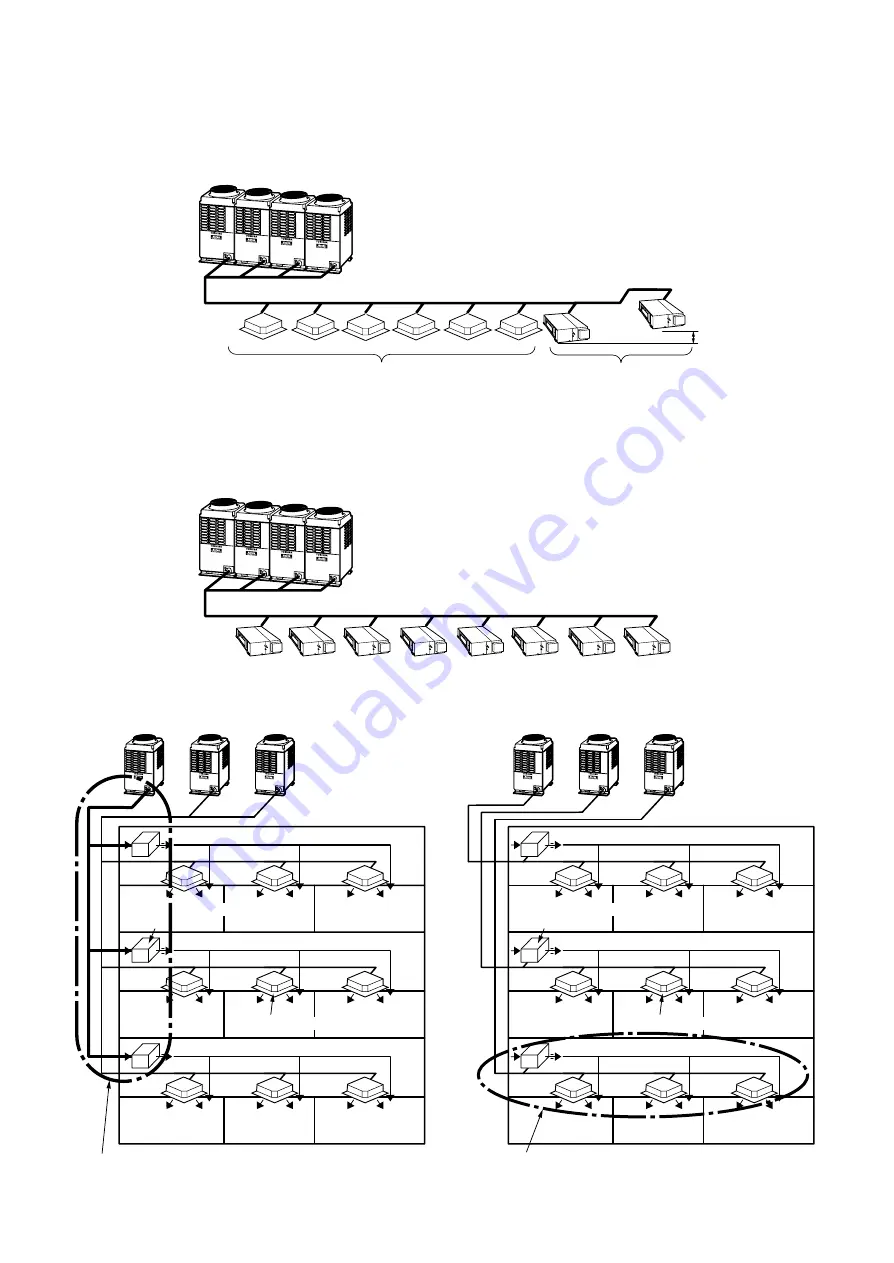

OK

80 to 100% to capacity of the outdoor units

Up to two fresh air intake indoor units

occupy 30% or less against

total capacity of indoor units

0.5m or less

NO GOOD

OK

NG

Outdoor unit

Inside of ceiling

All fresh air intake indoor unit system

Indoor air conditioner

Outdoor unit

Intermingled system with

indoor air conditioner

Fresh air intake

indoor unit

Indoor air conditioner

fresh air intake

indoor unit

Fresh air intake

indoor unit

Keep the height difference between the fresh air intake indoor units to 0.5m or less.

• The fresh air intake indoor unit is usually used together with the indoor units on one line of the multi system.

The fresh air intake indoor unit only cannot be connected.