– 31 –

Service plate

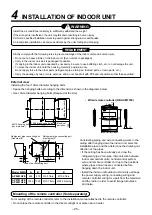

Pour water into the drain pan using hose, etc.

c.

6

DRAIN PIPING WORK

CAUTION

• Following the Installation Manual, perform the drain piping work so that water is properly drained, and apply a heat

insulating so as not to cause a dewing. Inappropriate piping work may result in water leakage in the room and wet

of furniture.

REQUIREMENT

• The draining method is a natural draining. Therefore, slope the piping outside of the unit downward

(at 1/50 to 1/100), and do not put an angle halfway. If doing so, an abnormal sound may be caused.

• To prevent overflow of drain pipe, set a drain trap on its way as shown in the right figure.

[The drain trap is required for preventing aspiration of smell through the drain pipe, and also for preventing

hardness of draining because the differential pressure between the drain pan and atmosphere becomes large

when the external static pressure is high (especially, at suction side).]

• Dust inside of the drain pipe is easy to be heaped at the drain trap.

Be sure to set a plug so that the drain trap can be cleaned.

• Maximum horizontal drain pipe length should be less than 20m or shorter.

If the pipe is long, set the support brackets with 1.5 to 2m interval to prevent waving.

• Mount the collective drain pipe as shown in the right figure.

• Do not mount an air purge pipe.

Otherwise drain water spouts out resulted in water leak.

• Do not apply strength to the connecting part with the drain pipe.

• Do heat insulating securely to the indoor drain pipe.

• Be sure to do heat insulating to the connecting part with the

indoor unit. Incomplete heat insulating may cause dewing.

• Do not directly connect the drain pipe to the drainage, etc. with

ammonia smell; otherwise there is a possibility that ammonia

ingredient of the drainage passes through the drain pipe and corrodes the heat exchanger of the indoor unit.

Piping/Heat insulating material

The following materials as below for piping and heat

insulating prpcess are procured locally.

Piping

Hard vinyl chloride pipe

VP25 (Outer dia. : Ø32mm)

Heat insulator

Vesicant polyethylene :

Thickness 10mm or more

Check the draining

Check the water drainage is surely performed at the trial

operation. Check also no water leakage is found at the

pipe connecting part.

REQUIREMENT

• Be sure to check draining even if installing the unit in heating season.

• Using a kettle or hose, pour water gradually from the drain pan at the air supply port.

Drain up

When not securing down slope on the drain pipe, use a

drain up kit sold separately.

Also refer to the “Drain up kit installation manual”.

Check the draining

After drain piping work, check that water drain is properly

performed and water does not leak from the connecting

part of the pipes.

In this time, check also there is no abnormal sound of the

motor of the drain pump.

Be sure to check draining when installed in the heating

period.

VP-30

Keep long as possible

(Approx. 10cm)

Downward pitch

1/100 or more