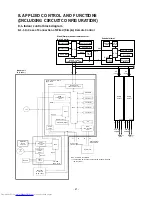

8. APPLIED CONTROL AND FUNCTIONS

(INCLUDING CIRCUIT CONFIGURATION)

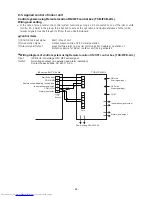

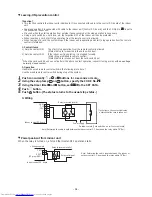

8-1. Indoor control block diagram

8-1-1. In Case of Connection of Wired (Simple) Remote Control

Same

as left

A

B

L

1

U1 U2

L2

Power

supply

Outdoor

unit

CPU

DC5V

DC5V

*1

CN2

CN1

Wired (Simple) header remote control

(Up to 2 units)

Schedule timer

Function setup

LCD

driver

CPU

Power

circuit

Power

circuit

Remote control

communication circuit

Display

LCD

Display LCD

EEPROM

Display LED

Secondary

battery

Key switch

Function setup

Key switch

Same

as left

#2

A

B

L1

U1 U2

L2

Power

supply

Outdoor

unit

(Follower)

#3

(Follower)

Remote conrol

communication circuit

MCU

EEPROM

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

HA

Driver

Start/Alarm/Ready

PMV

BUS

communication

circuit

Power

circuit

Outdoor unit

Power supply

1

Φ

208 / 230V, 60Hz

Indoor/Outdoor

communication

U1

U2

L2

L1

Outside output

DC12V

DC5V

DC20V

Indoor control P.C. Board

(MCC-1643)

Indoor

fan

motor

Reactor

Power

circuit

MCU

Fan motor

control

DC5V

DC15V

Fan IPDU

(MCC-1610)

Noise filter

P.C. Board

(MCC-1551)

Indoor

unit

#1

(Header)

A

B

Max. 8 units are connectable.

*1 The schedule timer cannot be connected to the simple wired

remote control.

UART

commnucation

circuit

UART

commnucation

circuit

Application

control

P.C.Board

- 21 -

c

ircuit