49

(

∗

)

¡

: Goes on,

¥

: Flashes

,

l

: Goes off

A

(Alter

nate)

: Flashing condition is alter

nate when there are tw

o flashing LED

.

S (Sim

ultaneously)

: T

w

o LED flash sim

ultaneously when there are tw

o flashing LED

.

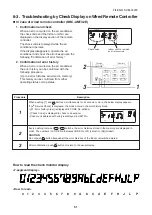

Chec

k code displa

y

TCC-LINK central & remote contr

oller

s

P07

(P09)

(P10)

P13

P15

P17

P18

P19

P20

P24

Sensor lamp displa

y

Bloc

k displa

y

Operation

Timer

Ready

Flash

¥

l

¥

A

l

¥¥

A

l

¥¥

A

l

¥¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

¥

l

¥

A

Outdoor 7-segment

A

uxiliar

y code

01

:

Compressor 1 side

P07

02

:

Compressor 2 side

03

:

Compressor 3 side

P09

Detection of heat unit n

umber

P10

Detection of indoor unit n

umber

P13

—

P15

01:

TS condition

02

:

TD condition

P17

—

P18

—

P19

Detection of outdoor unit n

umber

P20

—

P24

Detection of heat unit n

umber

Main def

ective position

Heat sink o

verheat error

Heat unit w

ater-shor

tage error

There is indoor unit which o

verflo

w w

as detected.

Outdoor liquid bac

k detection error

Gas leak detection

Outdoor discharge (TD2) temp

. error

Outdoor discharge (TD3) temp

. error

4-w

ay

v

alv

e

in

ve

rt

error

High pressure protection oper

ation

Heat unit error (Main code)

Description

High temp

. error w

as detected in outdoor IGBT b

uilt-in temp

. sensor (TH).

There is heat unit which w

as been detected w

ater-shor

tage in 1 system.

(

←

Heat unit detected.)

There is abnor

mally stopped indoor unit which w

as been detected w

ater-o

verflo

w

in 1 system. (

←

Indoor unit detected.)

Liquid bac

k oper

ation w

as judged from refr

iger

ant cycle status

.

Outdoor suction temp

. sensor (TS1) contin

uously and repeatedly detected high

temper

ature o

ver standard v

alue

.

High temp

. error w

as detected in outdoor discharge temp

. sensor (TD2).

High temp

. error w

as detected in outdoor discharge temp

. sensor (TD3).

Refr

iger

ant cycle error w

as detected in heating oper

ation.

High pressure (Pd) sensor detected pressure o

ver standard v

alue

.

Heat unit detected error (Heat remote controller displa

ys detailed chec

k code

together with model n

umber

.)

FILE NO. SVM-1

40

7

8