4

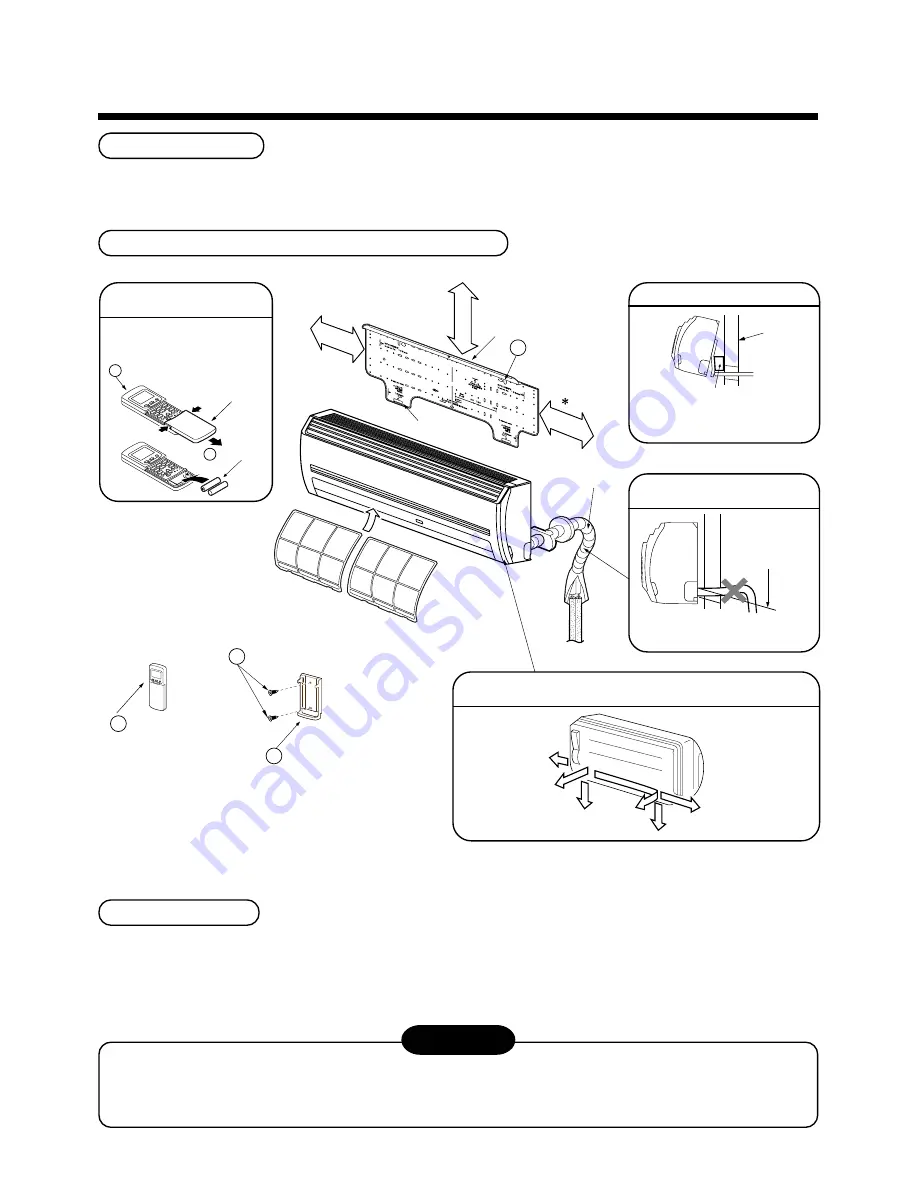

Installation space

Reserve space required to install the indoor unit and for service work.

Keep 100mm or more for clearance between top plate of the indoor unit and the ceiling surface.

Installation diagram of Indoor and outdoor units

The auxiliary piping can be connected the left, rear left, rear right,

right, bottom right or bottom left.

Before installing the

wireless remote controller

• With the remote controller cover

open, load the batteries supplied

correctly, observeing their polarity.

2 Wireless remote controller

3 Batteries

Cover

2

Wireless

remote controller

4

Remote control holder

Do not allow the drain hose to

get slack

Cut the piping hole

sloped slightly

Make sure to run the drain hose

sloped downward.

Left

Rear left

Right

Rear right

Bottom right

For the rear left and left piping

Wall

Insert the cushion between the

indoor unit and wall, and tilt the

indoor unit for better operation.

Bottom left

6

Pan head wood screw

Hook

170mm

or more

170mm

or more

100 mm or more

Hook

1

Installation

plate

Air filter

(Attach to the front panel)

Shield pipe

∗

When installing the Flow Selector Unit (FS Unit),

keep a space more than 300mm for wiring work.

Installation place

• A place which provides the spaces around the indoor unit as shown in the above diagram.

• A place where there is no obstacle near the air inlet and outlet.

• A place that allows easy installation of the piping to the outdoor unit.

• A place which allows the front panel to be opened.

CAUTION

• Direct sunlight to the indoor unit’ s wireless receiver should be avoided.

• The microprocessor in the indoor unit should not be too close to RF noise sources.

(For details, see the owner’ s manual.)