72

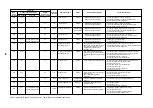

Error detected by TCC-LINK central control device

Error detected by AI-NET central control device

∗

These errors are concerned to communication of remote controllers (A, B) and central system [AI-NET X, Y], and the main remote controller displays [E01], [E02], [E03], [E09], or

[E18] in some cases and displays none in other cases according to the contents.

Check code

Display on

central control

device

C05

C06

C12

P30

Outdoor 7-segment display

Check code

Sub-code

—

—

—

(L20 is displayed.)

AI-NET

central control

remote controller

—

—

—

Detected

position

TCC-LINK

General-

purpose device

I/F

TCC-LINK

Check code name

TCC-LINK central control

device transmission error

TCC-LINK central control

device receiving error

Interface batch alarm of

general-purpose control

devices

Follower unit error of group

control

Duplicated central control

address

Status

Operation

continued.

Operation

continued.

Operation

continued.

Operation

continued.

Operation

continued.

Error detection condition

Signal is not transmit from central

control device.

Signal is not received from central

control device.

Error was input in general-purpose

control device control interface.

An error occurred in follower unit of

the group control.

([P30] is displayed only on the

central control remote controller.)

Central control addresses were

duplicated.

Check item (position)

• Check central control device error.

• Check communication line error of central control device.

• Check setup of end terminal resistance.

• Check central control device error.

• Check communication line error of central control device.

• Check setup of end terminal resistance.

• Check the power of connecting destination connected device.

• Check P.C. board error of the connected device.

• Check error input.

• Check the check code of the unit with alarm.

• Check the address setup.

Differs according

to error contents of the with alarm

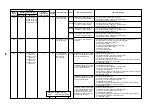

Check code

Main

remote

controller

—

—

—

Outdoor 7-segment display

Check code

Sub-code

—

—

—

—

—

—

AI-NET

central control

remote controller

97

99

b7

Detected

position

AI-NET

AI-NET

AI-NET

Check code name

AI-NET communication system

error

Duplicated network adaptors

Error in indoor group

Status

Operation

continued.

Operation

continued.

Operation

continued.

Error detection condition

E07/L07/L03/L08 was detected

when other indoor unit in the group

was defective.

Multiple network adaptors were

connected to communication line

of remote controller.

(Detected at central controller side)

Error of follower unit in the group

Check item (position)

• Check multiple network adaptors.

• Check wire and miswiring of remote controller: Only one

network adaptor can be connected to communication line of

remote controller.

• Check communication line, miswiring, and power of indoor unit.

• Check communication. (X, Y terminals)

• Check network adaptor P.C. board.

• Check the central controller

(Central control remote controller, etc.)

• Check follower unit in the group.