SMMS High-Wall Type

Installation Manual

– 42 –

EN

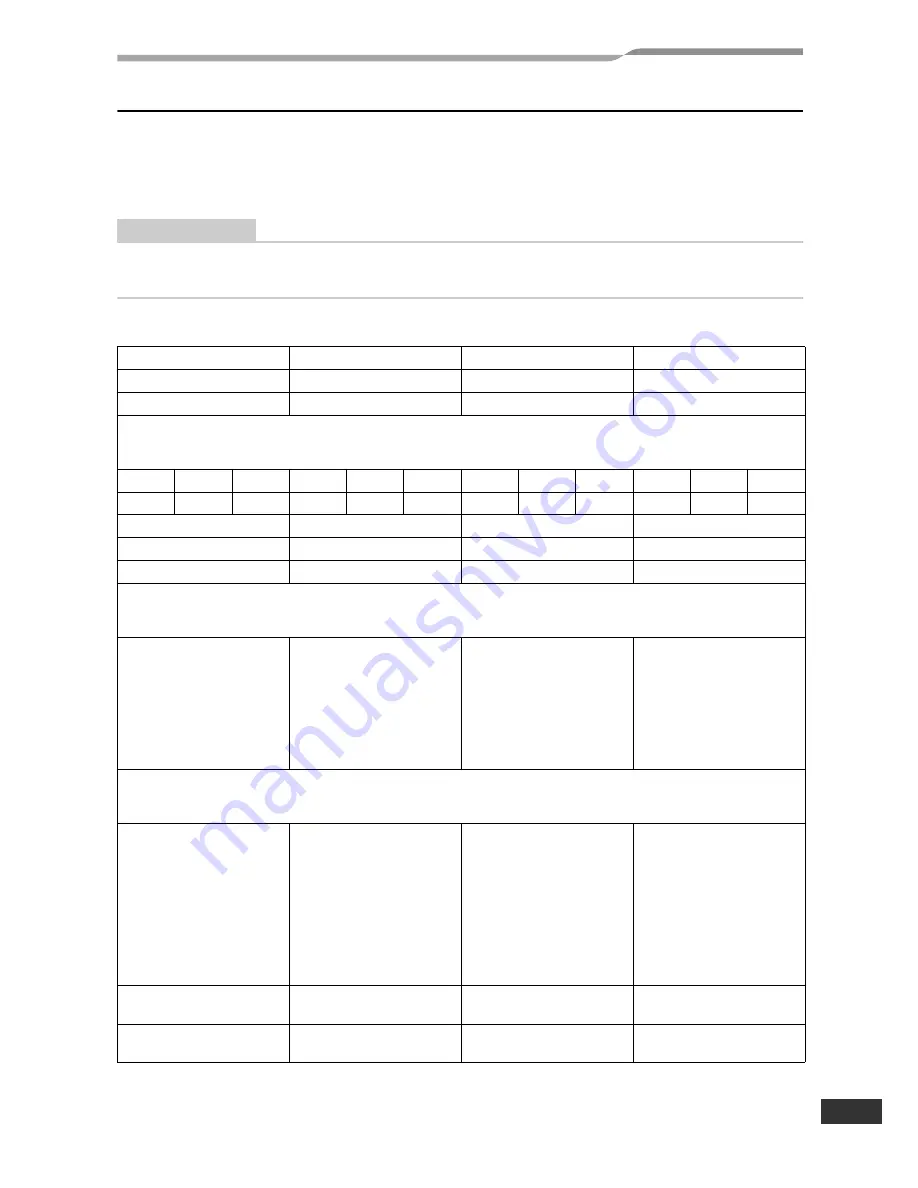

Confirmation of indoor unit setup

Prior to delivery to the customer, check the address and setup of the indoor unit, which has been installed

in this time and fill the check sheet (Table below). Data of four units can be entered in this check sheet.

Copy this sheet according to the No. of the indoor units. If the installed system is a group control system,

use this sheet by entering each line system into each installation manual attached to the other indoor units.

REQUIREMENT

This check sheet is required for maintenance after installation. Fill this sheet and then pass this Installation

Manual to the customers.

Indoor unit setup check sheet

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Room name

Room name

Room name

Room name

Model

Model

Model

Model

Check indoor unit address. (For check method, refer to APPLICABLE CONTROLS in this manual.)

*In case of a single system, it is unnecessary to enter the indoor address. (CODE NO.: Line [12], Indoor [13], Group

[14], Central control [03])

Line

Indoor

Group

Line

Indoor

Group

Line

Indoor

Group

Line

Indoor

Group

Central control address

Central control address

Central control address

Central control address

Various setup

Various setup

Various setup

Various setup

Have you changed lighting time of filter sign? If not, fill check mark [×] in [NO CHANGE], and fill check mark [×] in [ITEM]

if changed, respectively.

(For check method, refer to APPLICABLE CONTROLS in this manual.)

Filter sign lighting time

(CODE NO. [01])

NO CHANGE

NONE

[0000]

150H

[0001]

2500H

[0002]

5000H

[0003]

10000H

[0004]

Filter sign lighting time

(CODE NO. [01])

NO CHANGE

NONE

[0000]

150H

[0001]

2500H

[0002]

5000H

[0003]

10000H

[0004]

Filter sign lighting time

(CODE NO. [01])

NO CHANGE

NONE

[0000]

150H

[0001]

2500H

[0002]

5000H

[0003]

10000H

[0004]

Filter sign lighting time

(CODE NO. [01])

NO CHANGE

NONE

[0000]

150H

[0001]

2500H

[0002]

5000H

[0003]

10000H

[0004]

Have you changed detected temp. shift value? If not, fill check mark [×] in [NO CHANGE], and fill check mark [×] in

[ITEM] if changed, respectively.

(For check method, refer to APPLICABLE CONTROLS in this manual.)

Detected temp. shift value

setup (CODE NO. [06])

NO CHANGE

NO SHIFT

[0000]

+1°C

[0001]

+2°C

[0002]

+3°C

[0003]

+4°C

[0004]

+5°C

[0005]

+6°C

[0006]

Detected temp. shift value

setup (CODE NO. [06])

NO CHANGE

NO SHIFT

[0000]

+1°C

[0001]

+2°C

[0002]

+3°C

[0003]

+4°C

[0004]

+5°C

[0005]

+6°C

[0006]

Detected temp. shift value

setup (CODE NO. [06])

NO CHANGE

NO SHIFT

[0000]

+1°C

[0001]

+2°C

[0002]

+3°C

[0003]

+4°C

[0004]

+5°C

[0005]

+6°C

[0006]

Detected temp. shift value

setup (CODE NO. [06])

NO CHANGE

NO SHIFT

[0000]

+1°C

[0001]

+2°C

[0002]

+3°C

[0003]

+4°C

[0004]

+5°C

[0005]

+6°C

[0006]

Incorporation of parts

sold separately

Incorporation of parts

sold separately

Incorporation of parts

sold separately

Incorporation of parts

sold separately

Others ( )

Others ( )

Others ( )

Others ( )

Others ( )

Others ( )

Others ( )

Others ( )

42-EN

Summary of Contents for MMK-AP0074MH-E

Page 44: ...1111054499 ...