Chec

k code

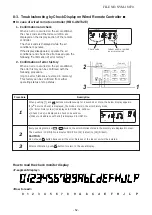

Wired remote

contr

oller

H15

H16

H25

L03

L04

Outdoor 7-segment displa

y

Chec

k code

A

uxiliar

y

code

H15

—

H16

01:

TK1 oil circuit system error

02:

TK2 oil circuit system error

03:

TK3 oil circuit system error

04:

TK4 oil circuit system error

05:

TK5 oil circuit system error

H25

—

——

L04

—

Detected position

I/F

I/F

I/F

Indoor

I/F

Chec

k code name

Outdoor unit discharge temp

. sensor (TD2)

mis

wir

ing

Oil le

vel detectiv

e

circuit system error

Outdoor unit discharge temp

. sensor (TD3)

mis

wir

ing

Duplicated indoor center units

Duplicated outdoor line address

Status

All stop

All stop

All stop

Corresponding unit only stops

.

All stop

E

rr

or detection condition

While compressor 2 is oper

ating,

the discharge temp

. (TD2) does

not r

ise up

.

Temperature change of

TK1 could

not be detected though compressor 1 star

ted the

oper

ation.

Temperature change of

TK2 could

not be detected though compressor 2 star

ted the oper

ation.

Temperature change of

TK3 could

not be detected though compressor star

ted the oper

ation.

Temperature change of

TK4 could

not be detected though compressor star

ted the operation, or the

diff

erence from other

TK sensor

changed f

or a constant time only

within the specified r

ange

.

Temperature change of

TK5 could

not be detected though compres- sor star

ted the operation, or the

diff

erence from other

TK sensor

changed f

or a constant time only

within the specified r

ange

.

While compressor 2 is oper

ating,

the discharge temp

. (TD3) does

not r

ise up

.

There are multiple center units in a group

.

Line address setup is duplicated against the outdoor unit in diff

erent

refr

igerant pipe system.

Chec

k item (position)

•

Chec

k mounting of

TD2 sensor

.

•

Chec

k connection and wir

ing of

TD2 sensor connector

.

•

Chec

k char

acter

istics of

TD2 sensor resistance v

alue

.

•

Chec

k outdoor unit P

.C

. board (I/F) error

.

•

Chec

k

TK1 sensor coming-off

.

•

Chec

k char

acter

istics of

TK1 sensor resistance v

alue

.

•

Chec

k TK1,

TK2, TK3,

TK4

and TK5

misconnection.

•

Chec

k oper

ation error of SV3E, SV3F v

alv

e.

•

Chec

k capillar

y clogging of oil-equation circuit and operation error of stop v

alv

e.

•

Chec

k refr

igerant stagnation in compressor

.

•

Chec

k

TK2 sensor coming-off

.

•

Chec

k char

acter

istics of

TK2 sensor resistance v

alue

.

•

Chec

k TK1,

TK2, TK3, TK4

and

TK5

misconnection.

•

Chec

k SV3E, SV3F v

alv

e oper

ation.

•

Chec

k capillar

y clogging of oil equalization circuit and chec

k stop v

alv

e oper

ation.

•

Chec

k refr

igerant stagnation in compressor shell.

•

Chec

k

TK3 sensor coming-off

.

•

Chec

k char

acter

istics of

TK3 sensor resistance v

alue

.

•

Chec

k TK1,

TK2, TK3, TK4

and

TK5

misconnection.

•

Chec

k SV3E, SV3F v

alv

e oper

ation.

•

Chec

k capillar

y clogging of oil-equalization circuit and chec

k v

alv

e operation.

•

Chec

k refr

igerant stagnation in compressor shell.

•

Chec

k

TK4 sensor coming-off

.

•

Chec

k char

acter

istics of

TK4 sensor resistance v

alue

.

•

Chec

k TK1,

TK2, TK3, TK4

and

TK5

misconnection.

•

Chec

k SV3E, SV3F v

alv

e operation.

•

Chec

k capillar

y clogging of oil-equalization circuit and chec

k v

alv

e operation.

•

Chec

k refr

igerant stagnation in compressor shell.

•

Chec

k

TK5 sensor coming-off

.

•

Chec

k char

acter

istics of

TK5 sensor resistance v

alue

.

•

Chec

k TK1,

TK2, TK3, TK4

and

TK5

misconnection.

•

Chec

k SV3E v

alv

e operation error

.

•

Chec

k capillar

y clogging of oil-equalization circuit and chec

k v

alv

e oper

ation error

.

•

Chec

k refr

igerant stagnation in compressor

.

•

Chec

k mounting of

TD3 sensor

.

•

Chec

k connection and wir

ing of

TD3 sensor connector

.

•

Chec

k char

acter

istics of

TD3 sensor resistance v

alue

.

•

Chec

k outdoor unit P

.C

. board (I/F) error

.

•

Chec

k indoor address

.

•

Chec

k the change of remote controller connection

(Group/individual) after indoor address setup

.

•

Chec

k line address

.

FILE NO. SVM-18070

- 62 -