‒

38

‒

38-EN

Installation Manual

13

TROUBLESHOOTING

A wired remote controller is necessary for this function. This function cannot be operate with a wireless

remote controller.

Con

fi

rmation and check

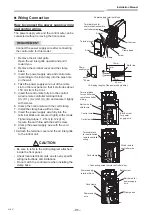

If a problem occurs with the air

conditioner, the OFF timer indicator

alternately shows the check code

and the indoor Unit No. in which

the problem occurred.

Check code

The indoor Unit No. in which

the problem occurred.

Troubleshooting history and con

fi

rmation

You can check the troubleshooting history with the following procedure if a problem occurs with the air

conditioner.

(The troubleshooting history records up to 4 incidents.)

You can check it during operation or when operation is stopped.

• If you check the troubleshooting history during OFF timer operation, the OFF timer will be canceled.

Procedure

Description of operation

1

Push the OFF timer button for over 10 seconds and

the indicators appear as an image indicating the

troubleshooting history mode has been entered.

If [ Service check] is displayed, the mode enters in

the troubleshooting history mode.

• [01: Order of troubleshooting history] appears in

the temperature indicator.

• The OFF timer indicator alternately shows the

[check code] and the [indoor Unit No.] in which the

problem occurred.

2

Each time the setting button is pushed, the recorded

troubleshooting history is displayed in sequence.

The troubleshooting history appears in order from

[01] (newest) to [04] (oldest).

CAUTION

In the troubleshooting history mode, DO NOT push

the Menu button for over 10 seconds, doing so

deletes the entire troubleshooting history of the

indoor unit.

3

After you have

fi

nished checking, push the ON/OFF

button to return to the regular mode.

• If the air conditioner is operating, it remains

operated even after the ON/OFF button has been

pushed.

To stop its operation, push the ON/OFF button

again.