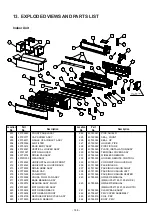

No.

Part name

P

rocedure

s

Remarks

5

Horizontal louver

6

1) Remove shaft of the horizontal louver

from the

drain pan

. (First remove 2 the

center shafts then remove the other shafts.)

Drain pan

Bend and

remove

Horizontal louver (Back)

Horizontal louver (Front)

Drain hose

1) Follow the procedure item 3 .

2) The drain hose can be removed by removing

the screw securing the drain hose and then

pulling out the drain hose.

3) When removing the drain hose, be careful of

any sharp edges of steel plate. The edges may

cause injury.

<To re-installation>

- To install the drain hose, insert the drain hose

firmly until the connection part contacts with

heat insulator, and then secure it with original

screw.

Screw

Drain hose

Steel plate

of Drain hose

Drain pan

Heat insulator

of drain pan

Drain pan

Drain hose

- 134 -

Summary of Contents for MMK- UP0301HP Series

Page 16: ...3 WIRING DIAGRAM 16 ...