GR

NL

PT

ES

IT

DE

FR

RU

SI

SK

LV

CS

TR

EN

Refrigerant piping

1. Use copper pipe with 0.8 mm or more thickness.

2. Flare nut and fl are works are also different from those

of the conventional refrigerant.

Take out the fl are nut attached to the main unit of the

air conditioner, and use it.

Permissible piping length and

height difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual attached

to the outdoor unit.

Flaring

• Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

• Insert a fl are nut into the pipe, and fl are the pipe.

As the fl aring sizes of R410A differ from those of

refrigerant R22, the fl are tools newly manufactured for

R410A are recommended.

However,

the

conventional tools can

be used by adjusting

projection margin of the

copper pipe.

Pipe size

(dia

: mm)

REQUIREMENT

When the refrigerant pipe is long, provide support

brackets at intervals of 2.5 to 3 m to clamp the refrigerant

pipe. Otherwise, abnormal sound may be generated.

CAUTION

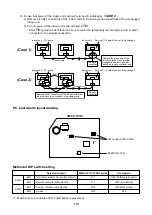

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of

the connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM

PUMP.

4. Check the gas leakage. (Connected points).

MML-

AP007 to

AP012 type

AP015 to

AP018 type

Gas side

9.5

12.7

Liquid side

6.4

6.4

Outer dia. of

copper pipe

R410A tool used

Conventional

tool used

R410A

R410A

6.4 , 9.5

0 to 0.5

1.0 to 1.5

12.7

Outer dia. of copper pipe

R410A

6.4

9.1

9.5

13.2

12.7

16.6

W

Projection margin in fl aring: B (Unit: mm)

Rigid (Clutch type)

W

Flaring dia. meter size: A (Unit: mm)

+0

-0.4

A

* In case of fl aring for R410A with the

conventional fl are tool, pull it out

approx. 0.5 mm more than that for R22

to adjust to the specifi ed fl are size.

The copper pipe gauge is useful for

adjusting projection margin size.

7

7

REFRIGERANT PIPING

REFRIGERANT

PIPING

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

Outer dia. of copper pipe

Tightening torque

6.4 mm (dia.)

14 to 18 (1.4 to 1.8 kgf·m)

9.5 mm (dia.)

33 to 42 (3.3 to 4.2 kgf·m)

12.7 mm (dia.)

50 to 62 (5.0 to 6.2 kgf·m)

W

Tightening torque of fl are pipe connections

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque wrench,

tighten the fl are pipe connecting sections which connect

the indoor and outdoor units of the specifi ed tightening

torque.

Incorrect connections may cause not only a gas leak, but

also a trouble of the refrigeration cycle.

Align the centres of the

connecting pipes and tighten

the fl are nut as far as possible

with your fi ngers. Then tighten

the nut with a spanner and

torque wrench as shown in the

fi gure.

Work using double spanner

(Unit: N·m)

25

25

REQUIREMENT

Tightening with an excessive torque may crack the nut

depending on installation conditions.

Tighten the nut within the specifi ed tightening torque.

Piping with outdoor unit

• Shape of valve differs according to the outdoor unit.

For details of installation, refer to the Installation

Manual of the outdoor unit.

REQUIREMENT

Use a leak detector manufactured exclusively HFC

refrigerant (R410A, R134a, etc.).

Open fully valves of the outdoor

unit

Heat insulation

Heat insulation for the pipes should be done separately

for the liquid side and gas side. Because both of the

liquid and gas side pipes become a low temperature

during cooling operation, suffi cient heat insulation should

be done to prevent condensation.

• Heat insulator with a heat resistance of 120°C or more

must be used for the gas side pipe.

• The pipe connection section of the indoor unit must

be heat insulated securely and compactly with the

attached heat insulator.

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant,

and gas leak check, follow the Installation Manual

attached to the outdoor unit.

WARNING

1. Using the specifi ed wires, ensure to connect the

wires, and fi x wires securely so that the external

tension to the wires do not affect the connecting

part of the terminals.

Incomplete connection or fi xation may cause a fi re,

etc.

2. Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

3. Appliance shall be installed in accordance with

national wiring regulations.

Capacity shortage of power circuit or incomplete

installation may cause an electric shock or a fi re.

CAUTION

• If incorrect/incomplete wiring is carried out, it will

cause an electrical fi re or smoke.

• Be sure to install an earth leakage breaker that is not

tripped by shock waves.

If an earth leakage breaker is not installed, an

electric shock may be caused.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core and

inner insulator of power and interconnecting wires

when peeling them.

• Use the power cord and Inter-connecting wire of

specifi ed thickness, type, and protective devices

required.

• Never connect 220–240V power to the terminal

blocks (

,

,

,

, etc.) for control wiring.

(Otherwise, the system will fail.)

8

8

ELECTRIC WORK

ELECTRIC

WORK

REQUIREMENT

• For power supply wiring, strictly conform to the

Local Regulation in each country.

• For wiring of power supply of the outdoor units,

follow the Installation Manual of each outdoor unit.

• Perform the electric wiring so that it does not come to

contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

• After connecting wires to the terminal blocks, provide

a trap and fi x wires with the cord clamp.

• Run the refrigerant piping line and control wiring line

in the same line.

• Do not turn on the power of the indoor unit until

vacuuming of the refrigerant pipes completes.

Indoor unit

Wrap the pipe with the attached

heat insulator without any gap

between the indoor unit.

Heat insulator (attached)

Banding band (attached)

Banding band (attached)

Fix with vinyl tape

Heat insulator of the local side pipe

102