60

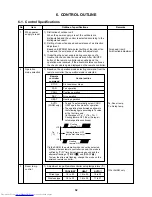

No.

18

Item

Louver contro

(Continued):

In case of

4-way Discharge

Cassette type

Outline of specifications

<<Selection of Swing mode>>

• For the Swing mode, the following three types of modes

are selectable and settable by keeping Swing/Direction

SWING/FIX

button pushed for 4 seconds or more on the remote

controller.

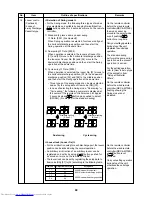

1) Standard (4 pieces: same phase) swing

→

Data: [0001 (At shipment)]

When Swing operation is selected, four louvers align at

the horizontal discharge position and then start the

Swing operation at the same time.

2) Dual swing

→

Data: [0002]

When operation is selected, the louvers of louver No.

[01] and [03] move to the horizontal discharge position,

the louvers of louver No. [02] and [04] move to the

downward discharge position and then start the Swing

operation at the same time.

3) Cycle swing

→

Data: [0003]

When operation is selected, the louver No. [01] moves to

the horizontal discharge position, [03] to the downward

discharge position, [02] and [04] to the middle position

and then start the Swing operation at the same time.

• Three types of the swing modes can be also selected

and set by the setup data of Item code (DN) [F0].

• In case of selecting the Swing mode, “Dual swing” or

“Cycle swing”, the following numerals is displayed at

the center of the remote controller screen for approx.

3 seconds when

SWING/FIX

button was pushed to select

[SWING]. (No display for the standard swing)

Remarks

On the remote controller

before the wired remote

controller (RBC-AMT32E),

the mode cannot be

moved to the select mode

even if pushing

SWING/FIX

button for a long time.

Carry out setting operation

during stop of the unit;

otherwise the unit stops

operation.

The standard swing

performs the same swing

operation as the present

operation (2 series).

For the setting operation,

refer to [How to set up type

of the swings] in Item

“Setup at local site/

Others”.

On the remote controller

before the wired remote

controller (RBC-AMT32E),

flashing showing the

Swing mode is not

indicated.

Dual swing

Cycle swing

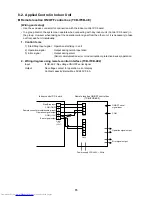

<<Louver lock (Louver fix)>>

• For the air direction setup for each discharge port, the louver

position can be locked during the normal operation.

• An arbitrary air direction of an arbitrary louver can be

registered and set by keeping

UNIT

LOUVER

button pushed for

4 seconds or more on the remote controller.

• The louver lock can be set by registering the setup data to

Item code (DN) [F1] to [F4] according to the following table.

On the remote controller

before the wired remote

controller (RBC-AMT32E),

UNIT

LOUVER

button is not

provided.

Carry out setting operation

during stop of the unit;

otherwise the unit stops

operation.

Alternate lighting

(0.5 sec.)

Alternate lighting

(0.5 sec.)

Item code

F1

F2

F3

F4

Objective louver No.

01

02

03

04

Setup data

0000: Release (At shipment)

0001: Horizontal discharge position

~

0005: Downward discharge position