Toshiba

– 10 –

SMMS 4-way Air Discharge Cassette Type

Installation Manual

EN

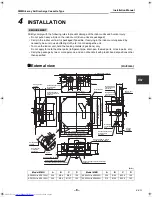

Installation of ceiling opening and

hanging bolt

• Attach a nut (M10 or W3/8: not supplied) and

the Ø34 washer (supplied) to each hanging bolt.

• Insert a washer on both sides of the T groove of

the hanging bracket of the indoor unit, and hang

the indoor unit.

• Check that the four sides of the indoor unit are

level using a level vial (levelness: 5mm or less).

• Detach the installation gauge (accessory) from

the installation pattern.

• Using the installation gauge, check and adjust

the positional relation between the indoor unit

and the ceiling opening (1) (10 to 35mm:

4 sides) and the hanging-up height (2)

(

mm: 4 corners).

(How to use the installation gauge is printed on

the gauge.)

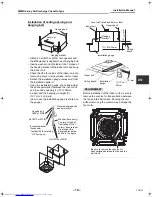

REQUIREMENT

Before installation of the indoor unit, be sure to

remove the cushion for transportation between

the fan and the bell mouth. Running the unit

without removing the cushion may damage the

fan motor.

Hanging bolt

Level vial

Hanging bracket

12

Washer (Accessory)

To prevent the bolt

from falling off (for

safety), be sure to set

it just under the

hanging bracket as

shown in the figure.

Eccentric washer

(Accessory)

Nut (M10 or W3/8)

Hanging bolt

(M10 or W3/8)

Nut (M10 or W3/8)

* Procure hanging bolts

and nuts locally.

* Install with the marking

“UP” facing up.

Indoor unit

Level vial (levelness: 5mm or less)

Hanging bolt

Hanging

bracket

Installation gauge

(1) 10 to 35mm

Ceiling

board

(2) m

m

12

Indoor unit

Installation

gauge

(1) 10 to

35mm

(2)

mm

12

Ceiling board

Be sure to remove the cushion for

transportation between the fan and the

bell mouth.

10-EN

+00EH99863501_6L_SMMS_4-way_IM1_printOnly.book Page 10 Thursday, September 11, 2008 9:29 AM

Summary of Contents for MMU-AP0092H

Page 38: ... 217 MEMO ...