– 103 –

FILE NO. SVM-

16041

Step6

Checkthesettingdatadisplayedatthistimewiththesettingdatadownin

[1]

(onpage104).

1. If the setting data is different, modify the setting data by pushing

/

buttons for the timer setting to

the data put down in

[1]

. The operation completes if the setting data is displayed.

2. If the data is the same, proceed to next step.

Step 7

Change the CODE No. (DN) by pushing

/

buttons for the temperature setting.

As described above, check the setting data and modify to the data put down in

[1]

.

Step 8

Repeat the steps 6 and 7.

Step 9

After the setting completes, push

TEST

button to return to the normal stop status.

6

In a group operation, turn off the power supply once, return the group wires between indoor units and

CN41 connectors as before, and then turn on power of all the indoor unit.

(It takes approx. 1 min until the remote controller operation is available again.)

• The CODE No. (DN) are ranged from “

��

” to “

��

”. The CODE No. (DN) is not limited to be serial No.

Even after modifying the data wrongly and pushing

SET

button, it is possible to return to the data before

modification by pushing

CL

button if the CODE No. (DN) is not changed.

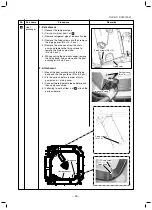

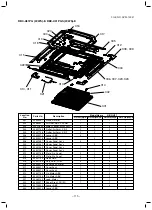

<Fig.3 EEPROM layout diagram>

The EEPROM (IC503) is attached to the IC socket.

When detaching the EEPROM, use a tweezers, etc.

Be sure to attach the EEPROM by fitting its direction as shown in the figure.

∗

Do not bend the IC lead when replacing.

<Fig. 3>

EEPROM

IC503

EEPROM

Cut out

Cut out

IC socket

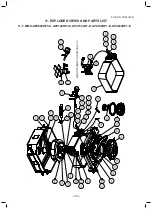

[3] Wiring the setting data to EEPROM

The settings stored in the EEPROM of the P.C. board for

indoor unit servicing are the factory-set values.

Step 1 Push

SET

,

CL

and

TEST

buttons on the remote controller

simultaneously for more than 4 seconds.

1

∗

In the group control operation, the unit No. displayed for

the first time is the header unit No.

(

is displayed in the Unit No. box.)

At this time, the CODE No. (DN) shows “

��

”. Also, the

fan of the indoor unit selected starts its operation and

the swing operation starts if it has the louvers.

Step 2 Every time when the

UNIT LOUVER

button is pushed, the indoor

unit Nos. in the group control operation are displayed in

order.

2

(The settings stored in the EEPROM of the P.C.

board for indoor unit servicing are the factory-set values.)

Specify the indoor unit No. with its P.C. board replaced to

the P.C. board for indoor unit servicing.

Step 3 Select the CODE No. (DN) can be selected by pushing the

/

button for the temperature setting.

3

• Set the indoor unit type and capacity.

The factory-set values shall be written to the EEPROM

by changing the type and capacity.

1. Set the CODE No. (DN) to “

��

”. (without change)

2. Select the type by pushing

/

buttons for the timer

setting.

4

(For example, 4-way Cassette Type in set to

“0001”. Refer to CODE No. [10] on page 122.)

3. Push

SET

button. (The operation completes if the setting

data is displayed.)

5

4. Change the CODE No. (DN) to “

��

” by pushing

/

buttons for the temperature setting.

3

5. Select the capacity by pushing

/

buttons for the timer setting.

4

(For example, 027 Type is set to “0012”. Refer to CODE No. [11] on page 104.)

6. Push

SET

button. (The setting completes if the setting data are displayed.)

5

Setting 4-way Cassette indoor unit model only

7. Using the set temperature

/

buttons, set “

��

” to the CODE No. (DN).

8. Using the timer time

/

buttons, set the dat. (0001)

9. Push

SET

button (The setting completes if the setting data are displayed.)

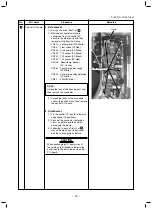

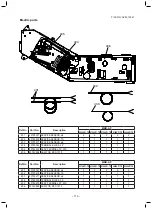

CAUTION

Be sure to set the jumper wire since the motor protection level setting selection is preformed on it.

If the plug short-circuit is attached on the P.C. board

before replacement, attach it on the P.C. board replaced.

CN34

(Red)

SW501

J01

J02

Connector

(CN504) for

drain pump

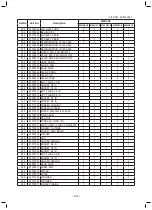

SET DATA

R.C.

No.

UNIT No.

CODE No.

TEMP.

ON / OFF

PROGRAM DAY

TIME

SAVE

TEMP.

ON / OFF

SETTING

SET DATA

UNIT

CODE No.

No.

R.C.

No.

SET

TIME

TIMER SET

TEST

FILTER

RESET

CL

FAN

SAVE

SWING/FIX

VENT

MODE

UNIT LOUVER

3

6

1

5

2

4

3

6

1

5

2

4

FILTER UP/DN

SCHEDULE

FAN

MODE

VENT

FLT.RESET TEST

SET CL

SWING/FIX

UNIT

LOUVER

∗

Set J02 as follows depending on the capacity class.

10.Push the

TEST

button to return to the normal stop status

(It takes approx. 1 min until the remote control operation is available again.)

Step 4 Write the on-site setting data to the EEPROM such as address setting, etc. Perform the steps 1 and 2

above again.

Step 5 Change the CODE No. (DN) to “

��

” by pushing

/

buttons for the temperature setting.

(This is the setting for the filter sign lighting time.)

AP009 to AP030 type

AP036 to AP056 type

Jumper wire (J02)

None

Required (Factory setting)

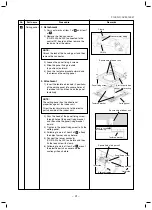

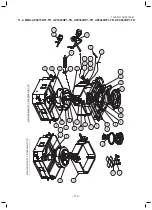

<Fig. 1 RBC-AMT32E>

<Fig. 2 RBC-AMS41E>