8

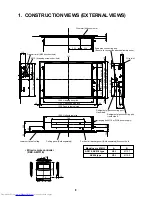

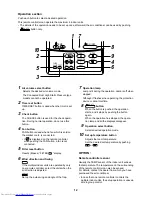

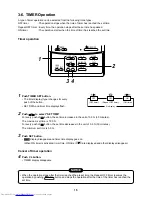

1. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

16

120

4

2.7

120

• Wired remote controller

(RBC-AMT31E)

Drain pipe connecting port

(Be sure to connect the attached flexible hose.)

Wire inlet

112

252

94

154

72

20

20

20

20

C/L

C/L

233

73.4

76

43

60

80

216

200

20

93

122

56

248

Wire inlet (Knockout hole)

Fresh air inlet (Ø92 knockout hole)

Ø112 (4-tapping screw under-hole)

710 Unit external size

1060 Hanging bolt pitch

1190 Ceiling opening size

1230 Panel external size

1000 Unit external size

475 Hanging bolt pitch

135

100

220

760 Ceiling opening size

800 Panel external size

706

Lower surface of ceiling

Ceiling panel (Sold separately)

For front air discharge unit (Sold separately) knockout hole

Hanging bolt M10 or W3/8 (Local supply)

Refrigerant pipe connecting port

Gas side B

Refrigerant pipe connecting port

Liquid side A

Model name MMU-

AP015, AP018 type

AP024 type

A

Ø6.4

Ø9.5

B

Ø12.7

Ø15.9

Summary of Contents for MMU-AP0152SH

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......