39

REQUIREMENT

[In Cooling operation]

• The operation starts after approximately 1 minute.

[In Heating operation]

• In heating operation, the fan operation may continue for approximately 30 seconds after the air condi-

tioner has stopped.

• The indoor fan continues in preheat operation for 3 to 5 minutes, and then blows out the hot air.

(

symbol is displayed on the remote controller.)

• When the temperature of the room has reached the set point temperature and after the unit has

stopped, the air speed

is lowered and the air volume is greatly reduced.

• In defrost mode, the fan stops so that cool air is not discharged.

PRE-DEF

symbol

is displayed.

[In Automatic operation]

• Using the difference between the set point temperature and the room temperature, the heating and

cooling operations are automatically performed.

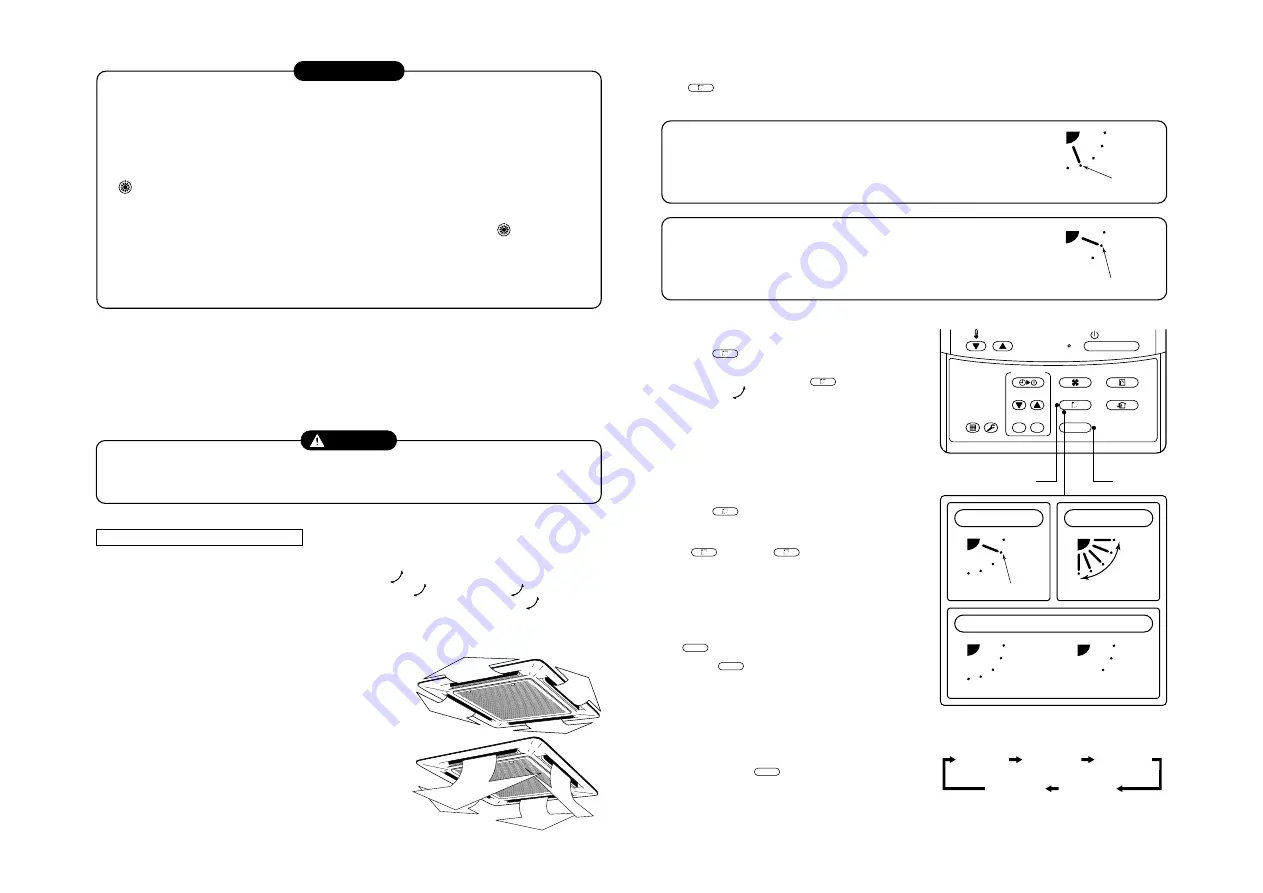

3-9. Adjustment of Wind Direction

To increase the cooling or heating effect, be sure to make proper use of the discharge louver for

cooling or heating operation.

As the characteristics of the air, cool air collects at lower levels, and hot air collects at higher levels.

CAUTION

Set the louver so that air blows out horizontally.

If cooling operation is performed with the louver blowing air downwards, the air outlet or surface of the

louver will be wet with dew, which may drip.

4-way Air Discharge Cassette Type

• While the air conditioner stops, the discharge louver directs downward automatically.

• When the heating operation is in PREHEAT/DEFROST

state, the louver is directed upward.

The rotation of the louver starts after PREHEAT/DEFROST

status cleared

, is displayed

on the remote controller even if the heating operation is in PREHEAT/DEFROST

status.

[In Cooling operation]

Use the discharge louver with horizontal set point.

[In Heating operation]

Use the discharge louver with downward set point.

How to set up the air direction

Push

SWING/FIX

button.

1

Every push of the button, the air direction changes.

In Heating operation

Set the air outlet louver downward.

If directing it upward, the hot air may not reach the floor.

In Cooling / Dry operation

Set the air outlet louver upward.

If directing it downward, dew condensation may fall on or near the air discharge port.

How to start louvre swinging

2

Push

SWING/FIX

button.

Set the louver direction to the lowest

position, and then push

SWING/FIX

again.

• [SWING

] is displayed and the air direction

automatically changes upward/downward.

In cases where one remote controller controls

the multiple indoor units, each indoor unit can

be selected and its air direction can be set up.

How to stop louver swinging

3

Push

SWING/FIX

button again while the louver is

operating.

• The louver stops at a position when you push

SWING/FIX

. If pushing

SWING/FIX

again, the air direction

descends from the highest position.

* In COOL/DRY operation, the louver does not

stop at the lowest position.

If stopping the louver as it directs downward

during operation, it stops after moving to the

3rd position from the highest position.

4

UNIT

• Push

UNIT

to set up the air direction individu-

ally in each indoor unit.

Then the indoor unit No. in a group control is

displayed.

For the displayed indoor unit, set up the air

direction.

• If the unit No. is not displayed, all the indoor

units are operated at the same time.

• Every time is

UNIT

pushed, the display is

exchanged as follows:

Initial setup

Initial setup

ON / OFF

FAN

TEMP.

SWING/FIX

TIME

MODE

VENT

UNIT

SET

CL

FILTER

RESET TEST

TIMER SET

In FAN operation

1, 2, 3

4

In all modes

Display when stopping the swing

Initial setup

Series of

operation

Fan/Heat

operation

Cool/Dry

operation

Unit No. 1-1

No display

Unit No. 1-2

Unit No. 1-4

Unit No. 1-3