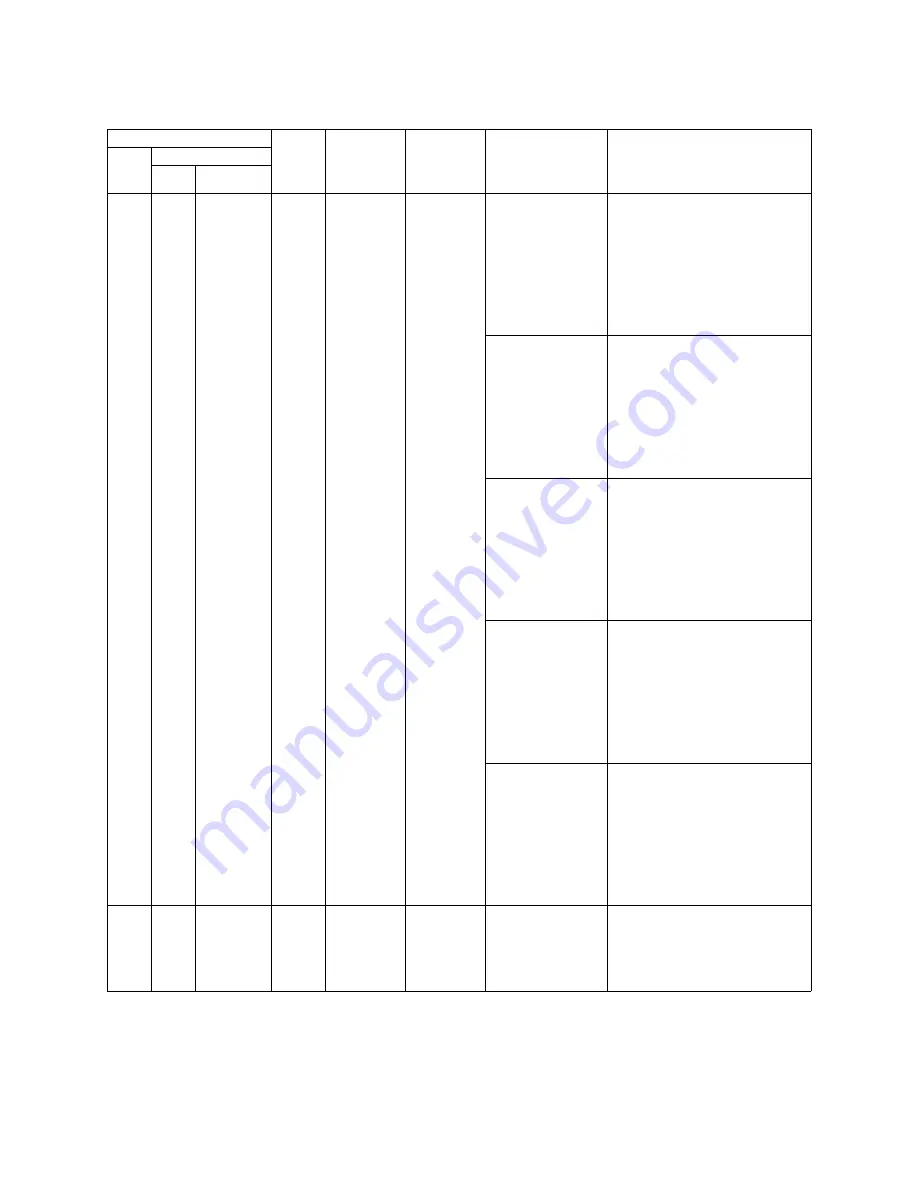

124

Check code

Location

of

detection

Description

System status

Error detection

condition(s)

Check items (locations)

Wired

remote

control

Outdoor 7-segment display

Check

code

Sub-code

H16

H16

01: TK1 oil

circuit error

02: TK2 oil

circuit error

03: TK3 oil

circuit error

04: TK4 oil

circuit error

05: TK5 oil

circuit error

I/F

Oil level

detection circuit

error

All stop

No temperature change is

detected by TK1 despite

compressor 1 having

been started.

• Check for disconnection of TK1 sensor.

• Check resistance characteristics of TK1

sensor.

• Check for connection error involving TK1,

TK2, TK3, TK4, and TK5 sensors

• Check for faulty operation in SV3E or SV3F

valve.

• Check for clogging in oil equalizing circuit

capillary and faulty operation in check

valve.

• Check for refrigerant entrapment inside

compressor.

No temperature change is

detected by TK2 despite

compressor 2 having

been started.

• Check for disconnection of TK2 sensor.

• Check resistance characteristics of TK2

sensor.

• Check for connection error involving TK1,

TK2, TK3, TK4, and TK5 sensors

• Check for faulty operation in SV3E or SV3F

valve.

• Check for clogging in oil equalizing circuit

capillary and faulty operation in check

valve.

• Check for refrigerant entrapment inside

compressor.

No temperature change is

detected by TK3 despite

compressor 3 having

been started.

• Check for disconnection of TK3 sensor.

• Check resistance characteristics of TK3

sensor.

• Check for connection error involving TK1,

TK2, TK3, TK4, and TK5 sensors

• Check for faulty operation in SV3E or SV3F

valve.

• Check for clogging in oil equalizing circuit

capillary and faulty operation in check

valve.

• Check for refrigerant entrapment inside

compressor.

No temperature change is

detected by TK4 despite

compressor having been

started.

• Check for disconnection of TK4 sensor.

• Check resistance characteristics of TK4

sensor.

• Check for connection error involving TK1,

TK2, TK3, TK4, and TK5 sensors

• Check for faulty operation in SV3E or SV3F

valve.

• Check for clogging in oil equalizing circuit

capillary and faulty operation in check

valve.

• Check for refrigerant entrapment inside

compressor.

No temperature change is

detected by TK5 despite

compressor having been

started.

• Check for disconnection of TK5 sensor.

• Check resistance characteristics of TK5

sensor.

• Check for connection error involving TK1,

TK2, TK3, TK4, and TK5 sensors

• Check for faulty operation in SV3E or SV3F

valve.

• Check for clogging in oil equalizing circuit

capillary and faulty operation in check

valve.

• Check for refrigerant entrapment inside

compressor.

H25

H25

–

I/F

TD3 sensor

miswiring

(incomplete

insertion)

All stop

Air discharge temperature

(TD3) does not increase

despite compressor 3

being in operation.

• Check installation of TD3 sensor.

• Check connection of TD3 sensor

connector and wiring.

• Check resistance characteristics of TD3

sensor.

• Check for defect in outdoor P.C. board (I/

F).

Summary of Contents for MMY-MAP0724HT6UL

Page 229: ...228 15Exploded Diagram Parts Price List SMMS i OUTDOOR UNIT MMY MAP0724HT6UL ...

Page 230: ...229 MMY MAP0724HT6UL ...

Page 232: ...231 SMMS i OUTDOOR UNIT MMY MAP0964HT6UL MMY MAP1144HT6UL ...

Page 233: ...232 MMY MAP0964HT6UL MMY MAP1144HT6UL ...

Page 237: ...236 SMMS i INV SERVICE PARTS LIST MMY MAP0724HT6UL 4 pieces PC board ...

Page 238: ...237 SMMS i INV SERVICE PARTS LIST MMY MAP0964HT6UL MMY MAP1144HT6UL 4 pieces PC board ...

Page 241: ...Copyright 2011 TOSHIBA CARRIER CORPORATION ALL Rights Reserved ...