– 9 –

17-EN

18-EN

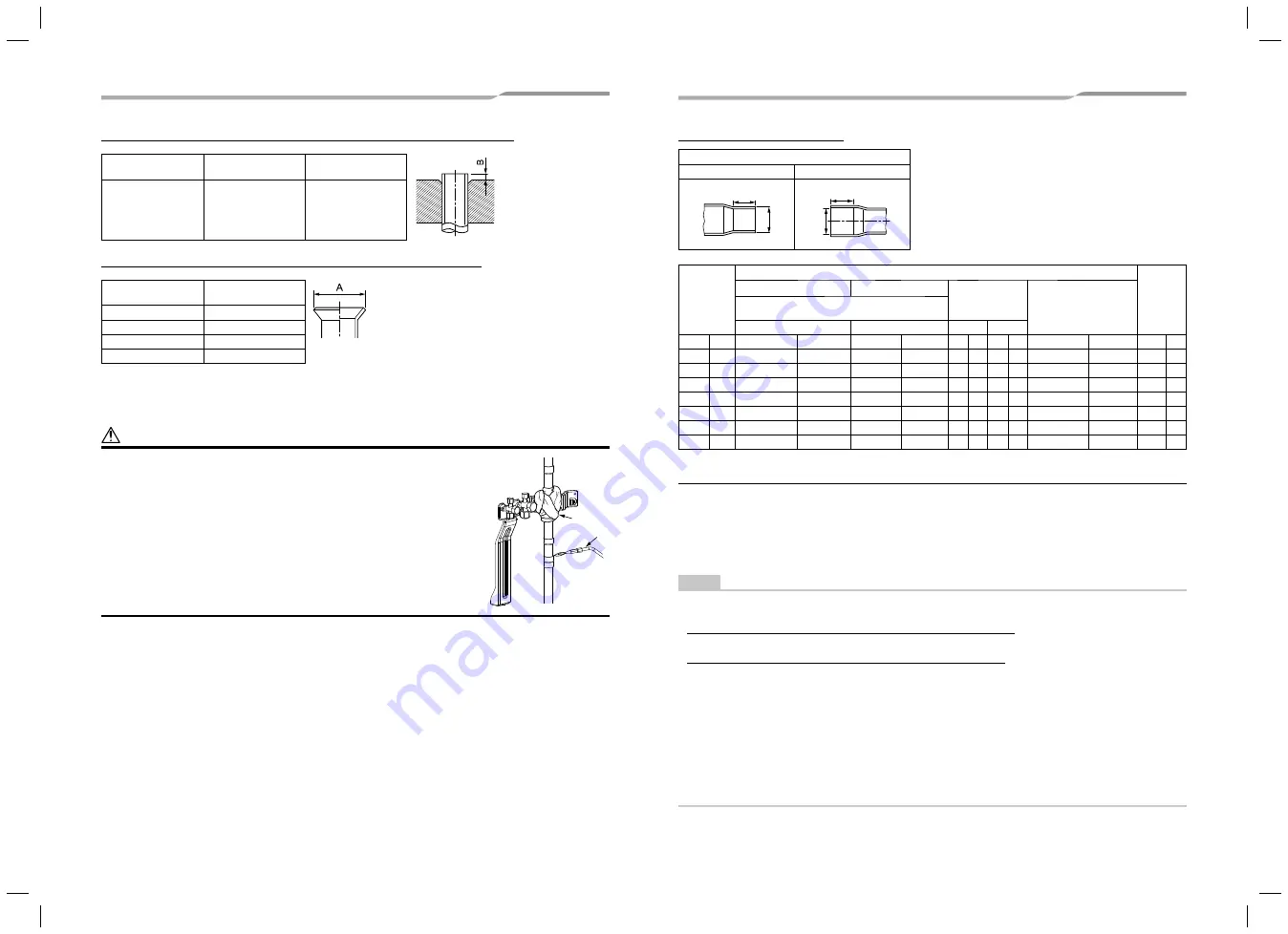

Extruding margin of copper pipe with

fl

are machining: B (Unit: in (mm))

Copper pipe outer

dia.

When using R410A

tool

When using

conventional tool

3/8" (9.5)

1/2"(12.7)

5/8" (15.9)

3/4" (19.1)

0 - 0.02"

(0 - 0.5)

0.04" - 0.06"

(1.0 - 1.5)

Extruding margin of copper pipe with

fl

are tools: A (Unit: in (mm))

Copper pipe outer

dia.

A

+0

–0.02" (–0.4)

3/8" (9.5)

0.52" (13.2)

1/2"(12.7)

0.65" (16.6)

5/8" (15.9)

0.78" (19.7)

3/4" (19.1)

0.94" (24.0)

* When using the conventional flare tool, to connect R410A pipes with flaring, make a margin approx.

0.02" (0.5 mm) longer than that of an R22 pipe so that the flare size matches the one specified. It is convenient

to use a copper pipe gauge for size adjustment of the extruding margin.

CAUTION

Wrap the ball valve in a wet cloth to keep it cool and prevent the heat from the

torch from damaging it when connecting the pipe to the ball valve on the gas line.

Cloth

Torch

Coupling size of brazed pipe

Connected section

External size

Internal size

K

ØC

G

ØF

Standard

outer dia.

of connected

copper pipe

Connected section

Min.

thickness

of

coupling

External size

Internal size

Min. depth of

insertion

Oval value

Standard outer dia.

(Allowable difference)

C

F

K

G

in

mm

in

mm

in

mm

in mm in mm

in

mm

in

mm

Ø1/4

6.35

1/4"(±0.0012)

6.35(±0.03) 0.25" (

+0.0016

−

0.0008

) 6.45 (

+0.04

−

0.02

) 0.28 7 0.24 6 0.0024" or less 0.06 or less 0.020" 0.50

Ø3/8

9.52

3/8"(±0.0012)

9.52(±0.03) 0.38" (

+0.0016

−

0.0008

) 9.62 (

+0.04

−

0.02

) 0.31 8 0.28 7 0.0031" or less 0.08 or less 0.024" 0.60

Ø1/2

12.7

1/2"(±0.0012) 12.70(±0.03) 0.5" (

+0.0016

−

0.0008

) 12.81 (

+0.04

−

0.02

) 0.35 9 0.31 8 0.0039" or less 0.10 or less 0.028" 0.70

Ø5/8 15.88 5/8"(±0.0012) 15.88(±0.03) 0.63" (

+0.0016

−

0.0008

) 16.00 (

+0.04

−

0.02

) 0.35 9 0.31 8 0.0051" or less 0.13 or less 0.031" 0.80

Ø3/4 19.05 3/4"(±0.0012) 19.05(±0.03) 0.76" (

+0.0012

−

0.0012

) 19.19 (

+0.03

−

0.03

) 0.43 11 0.39 10 0.0059" or less 0.15 or less 0.031" 0.80

Ø7/8

22.2

7/8"(±0.0012) 22.22(±0.03) 0.88" (

+0.0012

−

0.0012

) 23.36 (

+0.03

−

0.03

) 0.43 11 0.39 10 0.0063" or less 0.16 or less 0.032" 0.82

Ø1-1/8 28.58 1-1/8"(±0.0012) 28.58(±0.04) 1.13" (

+0.0024

−

0.0008

) 28.75 (

+0.06

−

0.02

) 0.51 13 0.47 12 0.0079" or less 0.20 or less 0.039" 1.00

■

Selection of pipe size

◆

Capacity code of indoor and outdoor units

Selection of pipe material

• For the indoor unit, the capacity code is decided at each capacity type. (Table 1)

• The capacity codes of the outdoor units are decided at each capacity type. The maximum number of connectable

indoor units and the total value of capacity codes of the indoor units are also decided. (Table 2)

NOTE

Compared with the capacity code of the outdoor unit, the total value of capacity codes of the connectable indoor

units differs based on the height difference between the indoor units.

When the height difference between the indoor units is 49 ft (15 m) or less

Total indoor capacity code must be between 50% and 135% of the capacity of the outdoor unit.

When the height difference between the indoor units is over 49 ft (15 m)

Total indoor capacity code must be between 50% and 105% of the capacity of the outdoor unit.

• If MMU-AP0072H2UL-1 or MMU-AP0122H2UL is included in the system, total indoor capacity code must be

between 80% and 100% of outdoor unit capacity.

• If MMD-AP

∗∗∗

BH is included in the system, total indoor capacity code must be,

• when the height difference between the indoor units is over 49 ft (15 m): between 80% and 105%

• when the height difference between the indoor units is 49 ft (15 m) or less: between 80% and 120%

* If the system con

fi

gure only the limited indoor unit type and limited number of connection indoor unit, total indoor

capacity code up to 150% of the outdoor capacity code is available when the height difference between the

indoor units is 49 ft (15 m) or less.

For more information, please refer to the engineering data book.

* Permanent operation below 80% is not recommended.

1122001201_EN FR.indd 9

1122001201_EN FR.indd 9

9/2/16 1:30 PM

9/2/16 1:30 PM