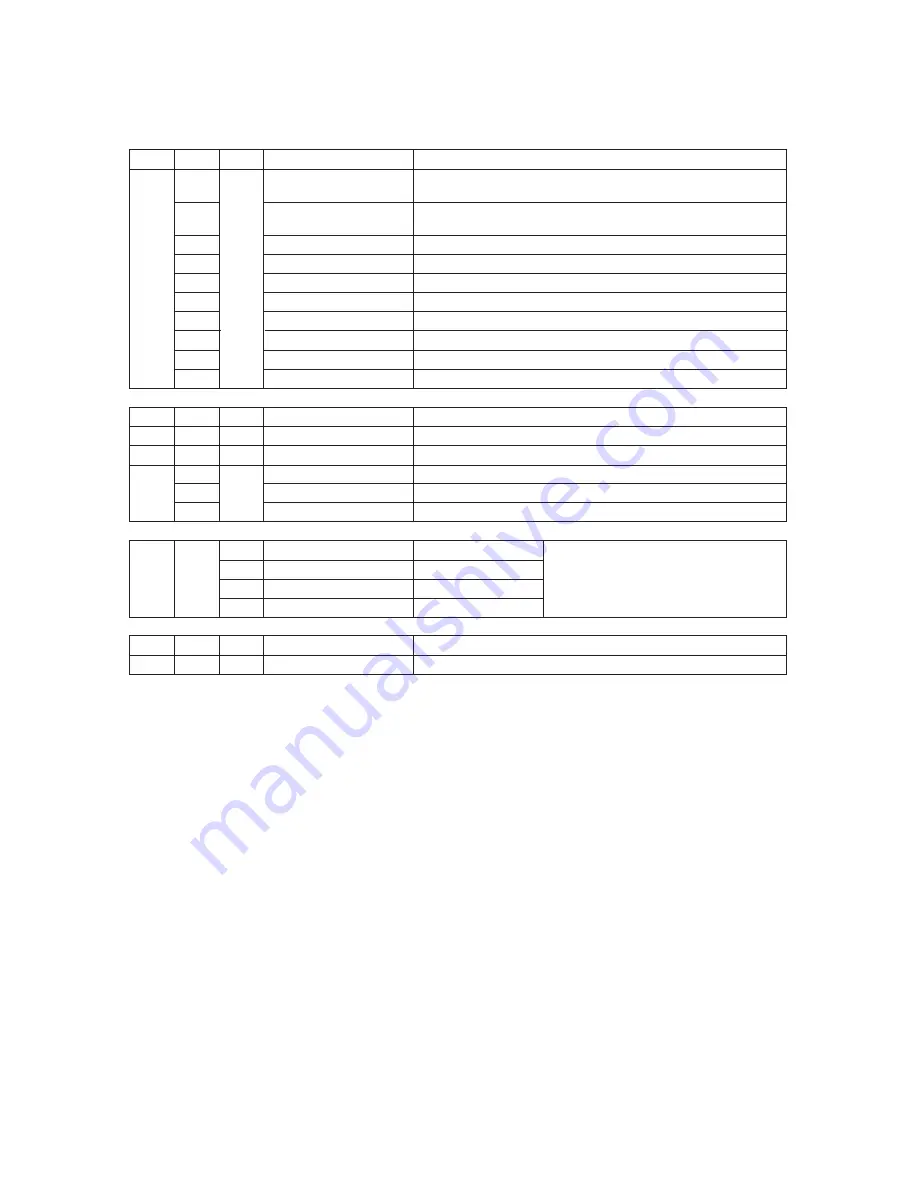

<Service support function list>

s

t

n

e

t

n

o

c

n

o

i

t

c

n

u

F

]

A

[

y

a

l

p

s

i

d

t

n

e

m

g

e

s

-

7

3

0

W

S

2

0

W

S

1

0

W

S

2

1

1

[J . C]

Refrigerant circuit and control communication line check function (Cooling

operation)

]

H

.

J

[

2

Refrigerant circuit and control communication line check function (Heating

operation)

n

o

it

c

n

u

f

n

e

p

o

l

l

u

f

d

e

c

r

o

f

V

M

P

r

o

o

d

n

I

]

.

P

[

3

n

o

it

c

n

u

f

g

n

it

a

n

i

m

ir

c

s

i

d

r

e

ll

o

rt

n

o

c

e

t

o

m

e

r

r

o

o

d

n

I

]

1

.

A

[

4

n

o

it

c

n

u

f

n

o

it

a

r

e

p

o

t

s

e

t

g

n

il

o

o

C

]

.

C

[

5

n

o

it

c

n

u

f

n

o

it

a

r

e

p

o

t

s

e

t

g

n

it

a

e

H

]

.

H

[

6

n

o

it

c

n

u

f

)

F

F

O

/

N

O

(

p

o

t

s

/t

r

a

t

s

e

v

it

c

e

ll

o

c

r

o

o

d

n

I

]

H

.

C

[

7

)

n

o

it

c

n

u

f

n

w

o

d

p

m

u

P

(

n

o

it

c

n

u

f

n

o

it

a

r

e

p

o

y

r

e

v

o

c

e

r

t

n

a

r

e

g

ir

f

e

r

r

o

o

d

t

u

O

]

d

.

r

[

1

1

Check code clear function

]r

.

E

[

6

1

2

1~16

3

[H . r]

Solenoid valve forced open/close function

2

4~7

[F . d]

Fan forced operation function

2

15

[t . o]

Outside temperature sensor manual adjustment function

16

1~16

1

[0 1]~[1 6]

Indoor No. 1 to 16 unit

Indoor individual start/stop (ON/OFF) function

2

[1 7]~[3 2]

Indoor No. 17 to 32 unit

3

[3 3]~[4 8]

Indoor No. 33 to 48 unit

4

[4 9]~[6 4]

Indoor No. 49 to 64 unit

s

t

n

e

t

n

o

c

n

o

i

t

c

n

u

F

]

B

/

A

[

y

a

l

p

s

i

d

t

n

e

m

g

e

s

-

7

3

0

W

S

2

0

W

S

1

0

W

S

1

1

1

[U 1] [ E28 ]

Follower unit check code / Corresponding unit fan operation function

1~16

1~16

−

14

3

−

9

[F . ]

Fan test operation function

14

[L . d]

Check of the refrigerant leakage detection

2

14

[C . i]

Check of the cooling initial valve

[H . i]

Check of the heating initial valve

13

15

Summary of Contents for MMY-MAP0806FT7(J)P

Page 32: ... 31 1 2 Single port FS Unit RBM Y1123FE FE2 RBM Y1803FE FE2 ...

Page 33: ... 32 RBM Y2803FE FE2 ...

Page 302: ...MMY MAP0806FT8 J P E MAP1006FT8 J P E MMY MAP0806FT8 J P TR MAP1006FT8 J P TR 301 ...

Page 307: ... 306 MMY MAP1206FT8 J P E MAP1406FT8 J P E MMY MAP1206FT8 J P TR MAP1406FT8 J P TR ...