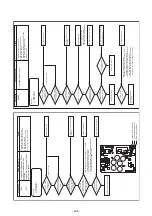

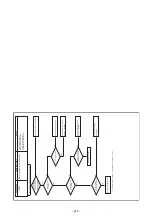

(*2) Checking the oil return circuit from oil separator and clogging in

SV3D valve

a)

Oil return circuit

•

While outdoor unit is operating, check temperature (secondary side of capillary) on oil return circuit.

((

2

) in the figure.)

If temperature is low equivalent to suction temperature), a clogging of strainer of oil return circuit or

capillary is considered. Replace the clogged part.

b)

Clogging check for SV3D valve

•

While outdoor unit is operated, set up SW01/02/03 = [2] [1] [3] (7-segment display [Hr] [... ... ...]), and

push SW04 for 1 seconds or more.

•

Set up SW02 = [4], and turn on SV3D valve. (7-segment display [Hr] [... 3 d])

•

If temperature is low at secondary side of the valve or it does not change, clogging of valve, capillary

,

or strainer is considered. ((

3

) in the figure.) Replace the clogged part.

In some cases, it may be dif

ficult to check the leakage of clogging in the following condition of refrigerant

stagnation in low ambient temperature condition.

In this case, take a longer operating time prior to check.

(Criterion: Discharge temperature of

TD1 and

TD2 are 60°C or higher)

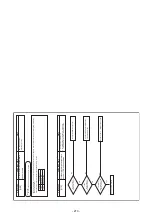

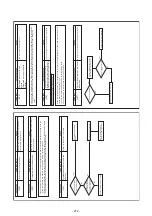

(*1) Checking leakage and clogging on SV3F valve

a)

Leakage check

• Turn off the power supply, take off connector of SV3F valve, and then start a test operation after

power ON.

• After operation for several minutes, check temperature at secondary side of SV3F valve.((1) in the figure)

→ If temperature is low, leakage occurs in the SV3F valve.

Replace SV3F valve.

b)

Clogging check

• While outdoor unit is operating, set up SW01/02/03=[2] [1] [3] (7-segment display [Hr] [... ... ...]), and

push SW04 for 2 seconds or more.

• Set up Sw02=[8], and turn on SV3F valve. (7-segment display [Hr] [... 3C])

• While outdoor units are operating, check temperature change at secondary side side of SV3F valve.

((1) in the figure.)

→ If temperature does not drop (equivalent to outside air temperature), it is a clogging of SV3F valve.

Replace SV3F valve.

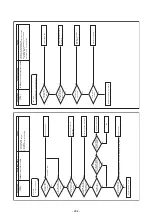

(*3) Checking the oil equalization circuit

a)

Clogging check for oil-equalization circuit

•

Drive the outdoor unit. (Drive all compressors in the unit.)

•

After driving for 10 minutes or more, check whether temperature of TK1, TK2 sensors and temperature

of oil-equalization circuit capillary ((

4

) in the figure) has increased.

(Criterion)

TK1, TK2=Td1, Td2 temperature - Approx. 10 to 30°C

Oil-equalization capillary tubes should be higher sufficiently than outside air temperature and suction

temperature.

•

If temperature is low, clogging of capillary or strainer is considered. Repair the failure parts.

TD

2

(T

D1)

SV

SV

ress

or 2

ter)

res

sor 1

er)

SV41

Hig

h-

pressure

sw

itch

Hig

h-

pressure

sw

itch

SV42

Oil separator

SV

SV3D

SV

SV3F

Accumulator

䌾

䌾

㩿

3

㪀

㩿

2

㪀

TK

2

TK

1

)

Compres

sor 2

(Invert

er)

Compres

sor 1

(Invert

er)

㩿㪈㪀

㩿

4

㪀

- 209 -

Summary of Contents for MMY-MUP0801HT7JP

Page 309: ......