10-1-3. Refrigerant recovery procedure B (Case that the troubled outdoor unit does not turn on)

<Outline>

If outdoor unit backup operation setting is performed, use an alternative refrigerant recovery procedure as

described below, provided that the power cannot be turned on for the troubled outdoor unit. (Refrigerant will be

recovered from the failed outdoor unit using the test cooling operation function.)

Note:

If the power cannot be turned on the troubled outdoor unit, the solenoid valves and PMVs of the unit

cannot be turned on, so that it reduces the amount of recovered refrigerant compared to a standard

reclaim operation. Recover the residual gas in the unit using a refrigerant recovery device, and be sure

to measure the amount of recovered refrigerant.

<Work procedure>

[Setup of troubled outdoor unit]

(1) Connect the liquid pipe check joint and the low pressure-side check joint using a gauge manifold, and

purge the manifold of air (to recover refrigerant from the heat exchangers).

(2) Fully close the liquid pipe packed valve of the troubled outdoor unit.

(Leave the service valve of the gas pipe fully open.)

[Setup of unit selected as header unit (hereafter “header outdoor unit”)]

(3) Set SW01/02/03 on the interface P.C. board of the header outdoor unit to 2/5/1. After [C. ] [… … …] is

displayed on the 7-segment display, press SW04 and hold for 5 seconds or more.

(4) After [C. …] [… – C] is displayed on the 7-segment display, the system starts operating in the test cooling

operation mode.

(5) Set SW01/02/03 on the interface P.C. board of the header outdoor unit to 1/2/2 to have the low-pressure

sensor\ output (MPa) displayed on the 7-segment display.

(6) Approx. 20 minutes after the system starts on , fully close the gas pipe service value of the failed outdoor unit.

(7) Press SW05 on the interface board to finish the reclaim operation.

(8) Turn off the power supply to all the outdoor units , and recover the resdual refrigerant in the outdoor unit

using a refrigerant recovery device. Be sure to measure the amount of recovered refrigerant.

(This is necessary to determine how much additional refrigerant will be needed after the completion of the

repair.)

This is the end of the refrigerant recovery operation.

Set SW01/02/03 of the troubled outdoor unit and the outdoor unit for pressure adjustment back to 1/1/1.

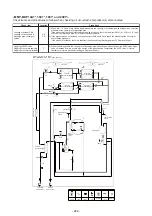

Header unit

(8)

Failure outdoor unit

Interface P.C. board of troubled outdoor unit

Turn off the power supply to all the outdoor

units , and recover the resdual refrigerant

in the outdoor unit using a refrigerant

recovery device. Be sure to measure

the amount of recovered refrigerant.

(7)

Press SW05 on the interface

board to finish the reclaim

operation.

(3) Set SW01/02/03 to 2/5/1.

[C. ] [... ... ...] is displayed.

↓

(4) Press SW04 and hold for 5 seconds or more.

[C. ...] [... – C] is displayed.

(Test cooling operation begins).

↓

(5) Set SW01/02/03 to 1/2/2 to have low-pressure

sensor output (MPa) displayed.

Pd→Ps→C–C

(6)

Approx 20 minutes after system startup,

fully close gas pipe service value.

(1)

Connect liquid pipe check joint and low

pressure-side check joint using charge

hose, and purge hose of air.

(2)

Fully close liquid pipe service value.

(Leave service valves of gas pipe

fully open.)

D600

SW01

1

D601

SW04

CN30

D602 D603 D604

SW02

1

SW03

1

SW05 SW06

CN31 CN32

- 259 -

Summary of Contents for MMY-MUP0801HT7JP

Page 309: ......