MR-2012 DISASSEMBLY AND REPLACEMENT

6 - 4

October 2000 © TOSHIBA TEC

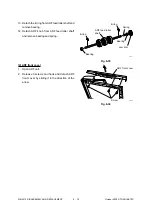

6. Remove Spring, ADF holder F, and washers in

this order, and remove timing belt.

7. Remove ADF pickup roller and ADF pickup feed

roller.

Note:

Apply 0.1g of Sumitec 505 No. 1 (white) to

the outer circumference of the spring.

Fig. 6-13

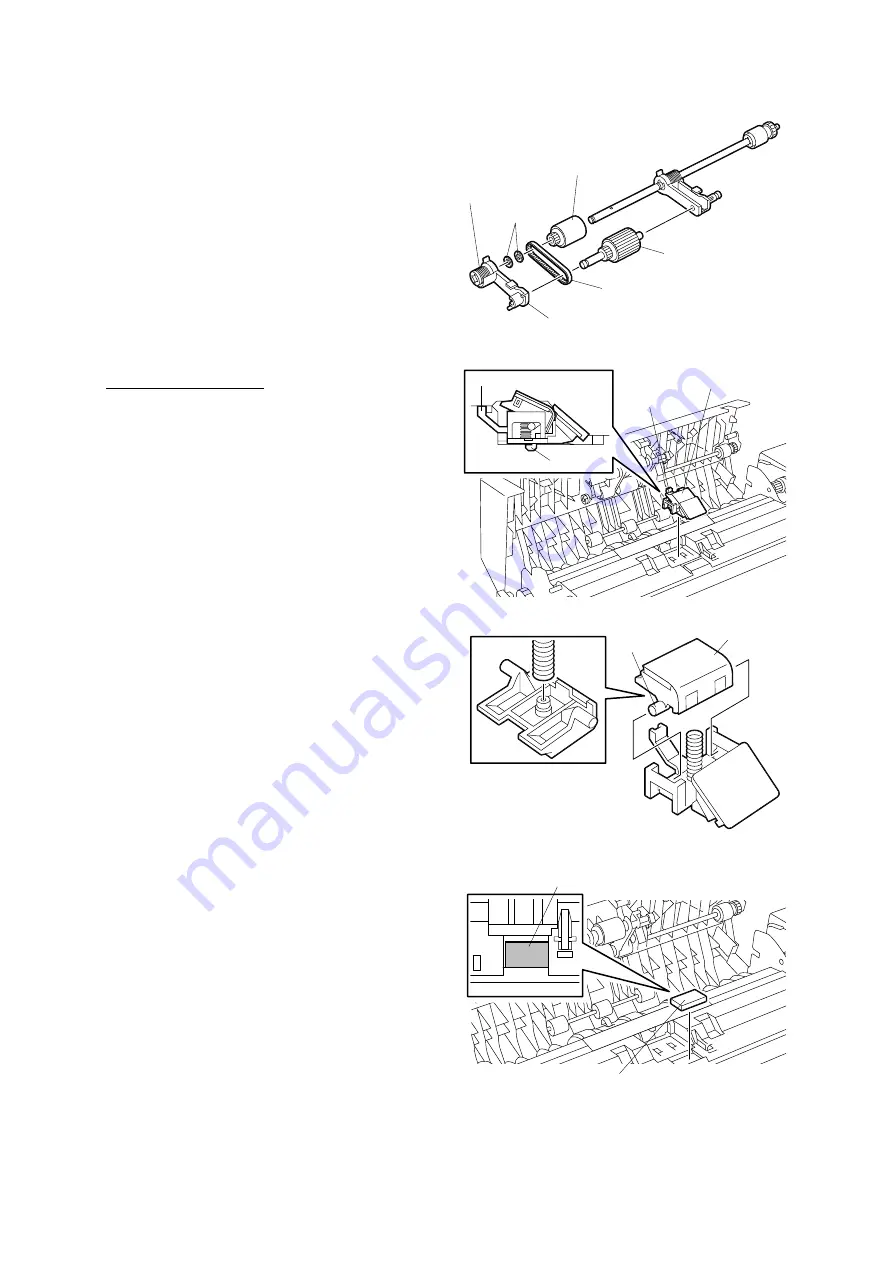

[G] ADF pad/brake pad

1. Open ADF top cover. (See Fig. 6-3)

2. Release the hook and remove ADF pad unit.

Fig. 6-14

3. Release the tab and remove ADF pad.

Fig. 6-15

4. Remove the old brake pad, wipe off the mount-

ing surface, and mount a new brake pad to the

position shown below.

Fig. 6-16

ADF pickup

feed roller

Spring

Washer

ADF pickup roller

Timing belt

ADF holder F

Hook

Hook

Hook

ADU pad unit

Tab

ADF pad

Brake pad

Brake pad

172

173

174

175