October 2000 © TOSHIBA TEC

3 - 3

MY-1015 OPERATIONAL DESCRIPTION

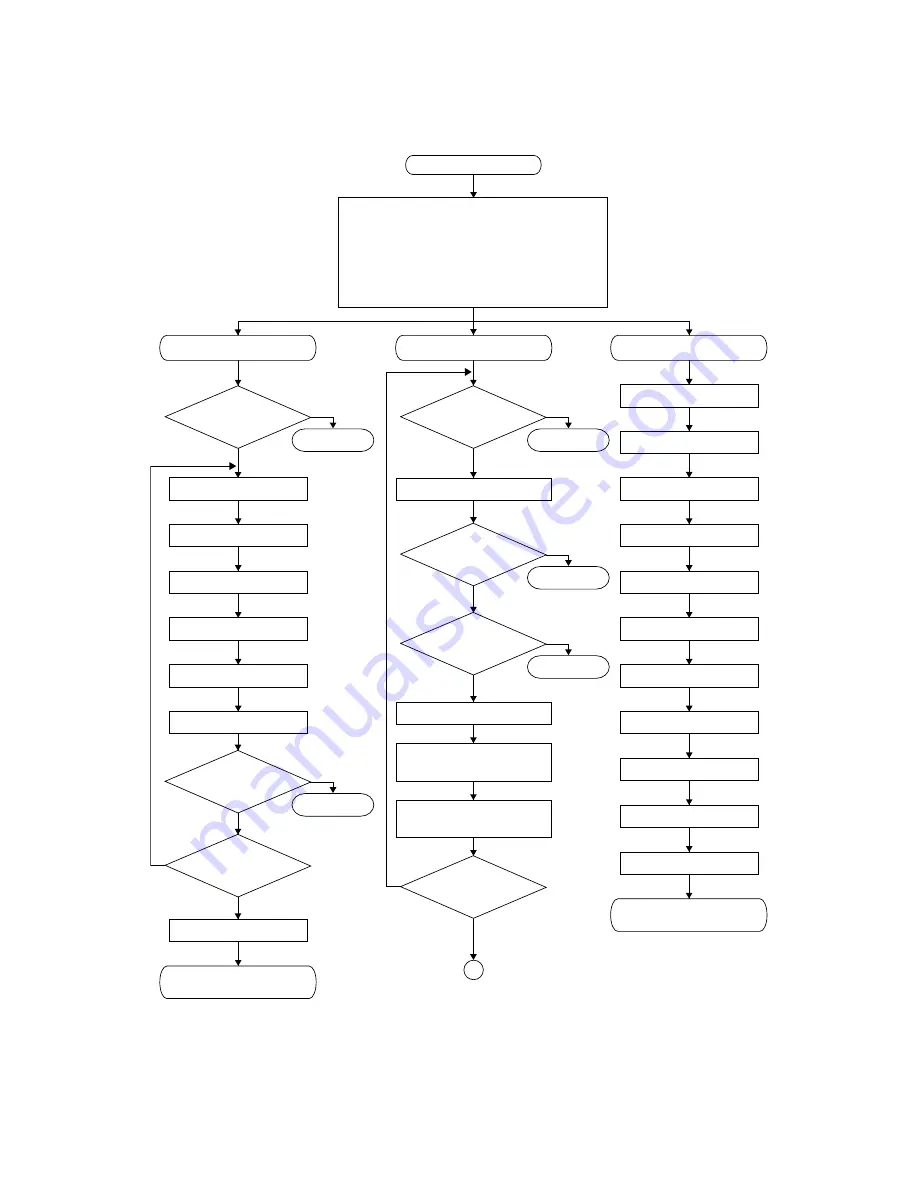

3.4 Flow Charts

Start button ON

Transfer system control

YES

Process system control

Optical system control

End of optical

system control

Main motor ON

Polygon motor ON

Process unit fan motor high speed rotation

Development bias ON

Separation bias ON

Charge bias ON

Discharge lamp ON

Main motor

OK?

PFU pickup clutch ON

Retraction of carriage

Black shading

Exposure lamp ON

Stop of carriage

Advance of carriage

White shading

Scanning of document

Stop of carriage

Exposure lamp OFF

Retraction of carriage

Stop of carriage

End of process

system control

Polygon motor OFF

Laser ON

Transfer bias ON

Transfer guide bias ON

Laser OFF

Transfer bias OFF

Transfer guide bias OFF

NG

Paper jam

"E14"

NO

Service call

"C01"

YES

Polygon motor

OK?

NO

Service call

"CA1"

OK

2nd feed

sensor check

NG

Paper jam

"E31"

OK

Feed sensor

check

YES

Remaining

copy count 0?

NO

NO

Service call

"CA2"

YES

HSYNC

OK

YES

Remaining

copy count 0?

A

PFU pickup clutch OFF

2nd feed clutch OFF

2nd feed clutch ON

NO