8

P9 ASD Quick Start Guide

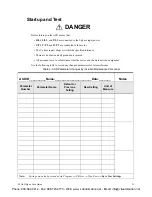

System Setup Requirements

•

With the exception of the

TBA Pump Number

(F434), ensure that all

Time-Based Alternation

parameter settings and the real-time clock settings for each ASD within the system are the same.

•

When using the ASD as an integral part of a larger system, it is the responsibility of the ASD

installer/maintenance personnel to ensure that there is a fail-safe in place (i.e., an arrangement

designed to switch the system to a safe condition if there is a fault or failure).

•

Power factor improvement capacitors or surge absorbers

MUST NOT

be installed on the output of

the ASD.

•

Use of the built-in system protective features is highly recommended (i.e., E-Off, Overload

Protection, etc.).

•

The operating controls and system status indicators should be clearly readable and positioned

where the operator can see them without obstruction.

•

Additional warnings and notifications shall be posted at the equipment installation location as

deemed required by

.

•

System safety features should be employed and designed into the integrated system in a manner

such that system operation, even in the event of system failure, will not cause harm or result in

system damage or injury to personnel (i.e., E-Off, Auto-Restart settings, System Interlocks, etc.).

•

The programming setup and system configuration of the ASD may allow it to start the motor

unexpectedly. A familiarity with the

Auto-Restart

(F301),

Sleep Timer

(F383), and the

Start-

Stop

(F385) settings are a requirement to use this product.

•

The setup procedures included within this guide may require a

Reset

before performing the

procedure. Application-specific settings may then be performed. The pre-Reset conditions may be

saved (See F007).

•

There may be thermal or physical properties, or ancillary devices integrated into the overall system

that may allow for the ASD to start the motor without warning. Signs to this effect must be posted

at the equipment installation location.

•

If a secondary magnetic contactor (MC) or an ASD output disconnect is used between the ASD and

the load, it should be interlocked to halt the ASD before the secondary contact opens. If the output

contactor is used for bypass operation, it must be interlocked such that commercial power is never

applied to the ASD output terminals (U, V, or W).

•

When using an ASD output disconnect, the ASD and the motor must be stopped before the

disconnect is either opened or closed. Closing the output disconnect while the 3-phase output of the

ASD is active may result in equipment damage or injury to personnel.

CAUTION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www .ctiautomation.net - Email: info@ctiautomation.net