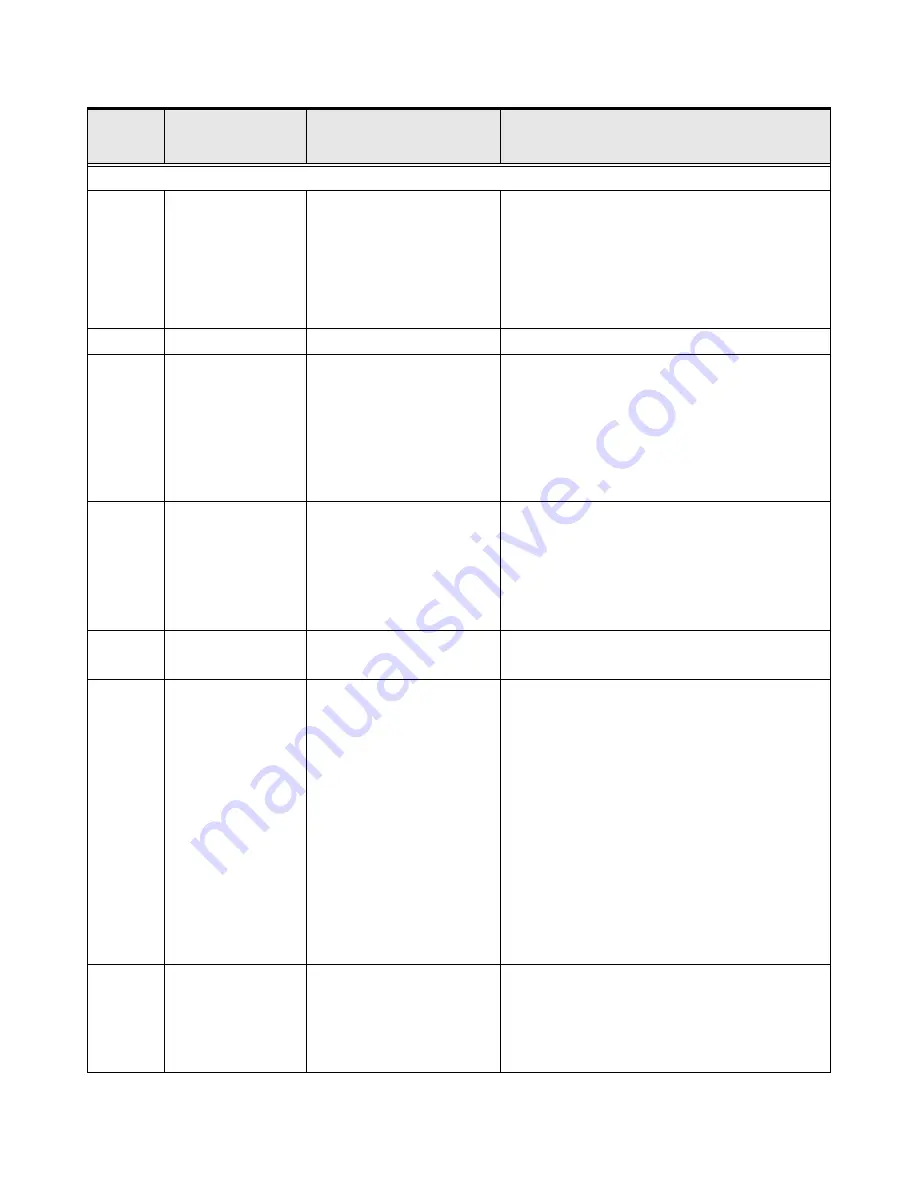

72

P9 ASD Quick Start Guide

*

Reset ignored if active.

*OH

Overheat

ASD ambient temperature

excessive.

• ASD is operating at an elevated temperature.

• ASD is too close to heat-generating equipment.

• Cooling fan vent is obstructed (See

).

• Cooling fan is inoperative.

• Internal thermistor is disconnected.

OJ

Timer

Run-time counter exceeded.

•

Type Reset

required; select

Clear run timer

.

*OLI

ASD Overload

Load requirement in excess of

the capability of the ASD.

• The carrier frequency is too high.

• An excessive load.

• Acceleration time is too short.

• DC damping rate is set too high.

• The motor is starting into a spinning load after a

momentary power failure.

• The ASD is improperly matched to the application.

OLM

Motor Overload

Load requirement in excess of

the capability of the motor.

• V/f parameter improperly set.

• Motor is locked.

• Continuous operation at low speed.

• The load is in excess of what the motor can deliver.

• Disconnected/damaged cable while operating in the PG

Feedback Vector Control mode.

*OLR

Resistor Overload

Excessive current at the

Dynamic Braking Resistor

.

• Deceleration time is too short.

• DBR configuration improperly set.

*OP

Over-Voltage

DC bus voltage exceeds

specifications.

Note:

It is normal for the

OP

alarm to flash during

decel when using the

Automatic Acc/Dec

setting at

F000

.

• ASD attempting to start into a spinning motor after a

momentary power loss.

• Incoming commercial power is above the specified

range.

• Decel time is too short.

• Voltage spikes at the 3-phase input; install inductive

filter.

• DBR required.

• DBR resistance value is too high.

• DBR function is turned off.

• Over-Voltage Stall feature is turned off.

• System is regenerating.

• Load instability.

• Disable the Ridethrough function (F302).

OT

Over-Torque

Torque requirement is in excess

of the setting of

F616

or

F617

for a time longer than the setting

of

F618

.

• ASD is not correctly matched to the application.

•

F616

or

F617

setting is too low.

• Obstructed load.

• Disconnected/damaged cable while operating in the PG

Feedback Vector Control mode.

LED

Screen

LCD

Screen

Description

Possible Causes/Troubleshooting

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www .ctiautomation.net - Email: info@ctiautomation.net