For additional assistance, please contact Toshiba Adjustable Speed Drive Marketing Dept. at (800) 872-2192

Page: 2 of 6

+

-

Pressure Transducer

(2-Wire)

P24

V/I

CC

IICC

4-

20

m

A

Connections

Depending on the type of transducer that is being used for process feedback, the wiring will be

different. The connection diagrams below show how to connect a 2-wire transducer and a 4-wire

transducer to the Q9.

2-Wire

When using a 2-wire transducer with a Toshiba drive, it is usually

powered from the P24 terminal (24 Vdc supply). The positive

terminal of the transducer is connected to P24 and the feedback

signal (4-20 mA) is connected from the negative terminal to the V/I

terminal.

Because the V/I terminal is an isolated analog input and the

transducer is powered from P24, the current loop will not be

complete. A jumper will need to be placed between CC and IICC

to make the V/I terminal non-isolated.

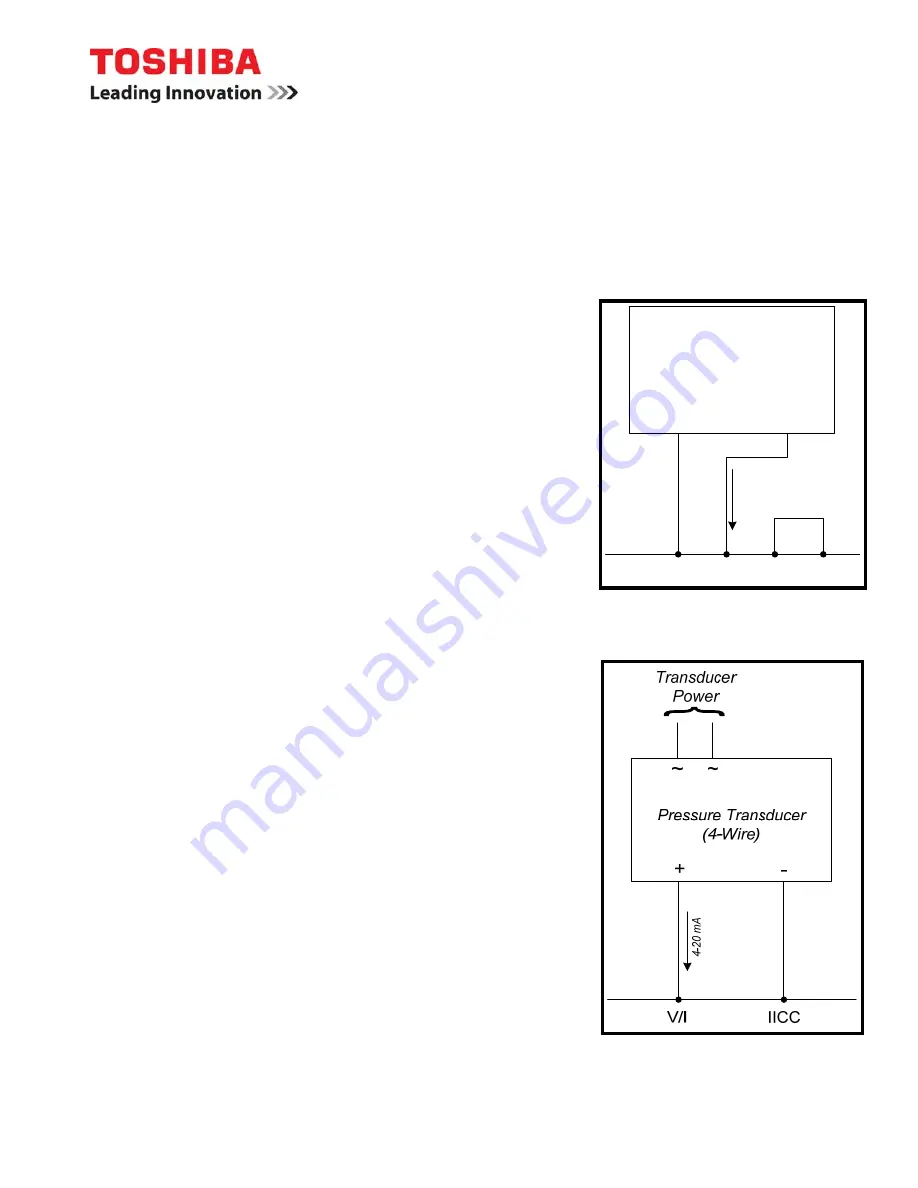

4-Wire

A 4-wire transducer is powered from an external source and does

not use the drive for power. Two of the wires will connect to the

external power source. The feedback signal will be connected

from the positive terminal of the transducer to the V/I terminal of

the drive. The return for the current loop will be connected from

the negative terminal of the transducer to the IICC terminal of the

drive.

Because the transducer is not being powered from the Q9, the V/I

terminal can remain isolated and there is no need to connect CC to

IICC.

Note:

When using a 4-20 mA signal as feedback into the V/I terminal, be

sure to set SW 301 to “I”.