– 11 –

•

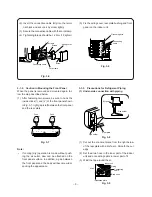

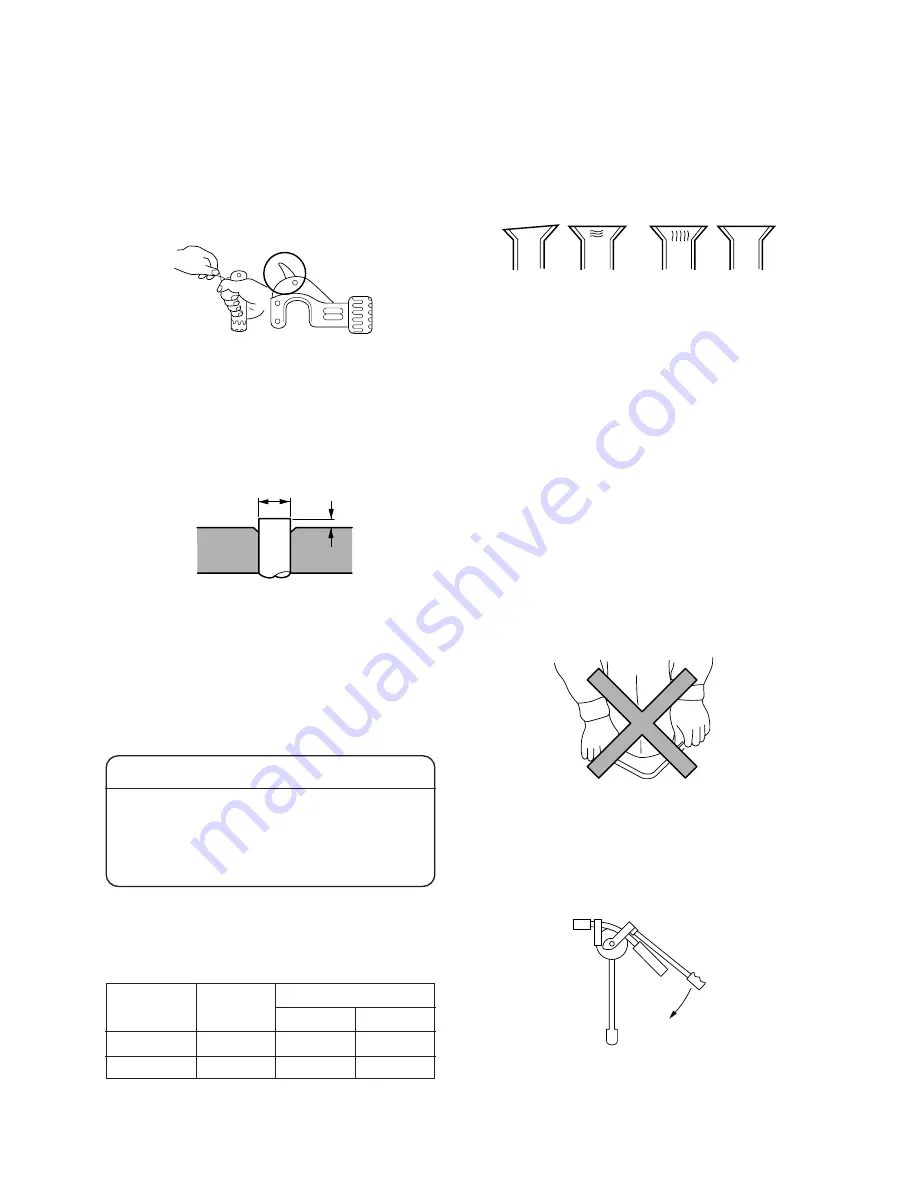

Fine flaring work shows even brightness on the

flared surface and uniform thickness of pipe.

•

Unsuccessful flaring work causes gas leaks,

therefore rework it.

Fig. 3-17

•

The above faulty flaring will cause gas leaks.

3-2-4. Finishing Work

(1) Fix the pipe firmly on the flare die. Match the cen-

ters of both the flare die and the flaring punch,

and tighten flaring punch fully.

3-3. Pipe Process Points

3-3-1. Pipe Bending

(1) Carefully bend by hand.

Note:

•

Collapsed pipe cause cooling failure.

Fig. 3-18

(2) Bend with pipe bender. (Since the insulation is

wound on, use the bender by sliding the insula-

tion to one side, or cutting it halfway.)

Fig. 3-19

Note:

•

Be sure to remove burrs to avoid unevenness on

the flare face which will cause gas leaks.

•

Cover the pipe end with a polyethylene bag and

on sheet.

Fig. 3-15

3-2-3. Point of Flaring

(1) The exact length of pipe protruding from the face

of the flare die is determined by the flaring, too.

Fig. 3-16

Note:

•

Too long a protrusion of pipe from the flaring tool

will result in too long a flare; If this happens, the

flare nut will not tighten and the joint will not seat.

•

Too small a protrusion will cause gas leaks.

CAUTION:

•

Too large protrusion of pipe results in impos-

sible tightening of the flare nut.

•

Too small a protrusion of pipe will cause gas

leaks due to insufficient flare surface.

•

Table 3-1 shows the use of an imperial die and a

rigid die.

Table 3-1

Imperial

1.3

1.6

Rigid

0.7

1.0

A (mm)

D (mm)

6.35

9.52

Type of pipe

1/4”

3/8”

A

D

Slant

Scratch

Crack

Uneven

thickness