−

77

−

FILE NO. SVM-06037

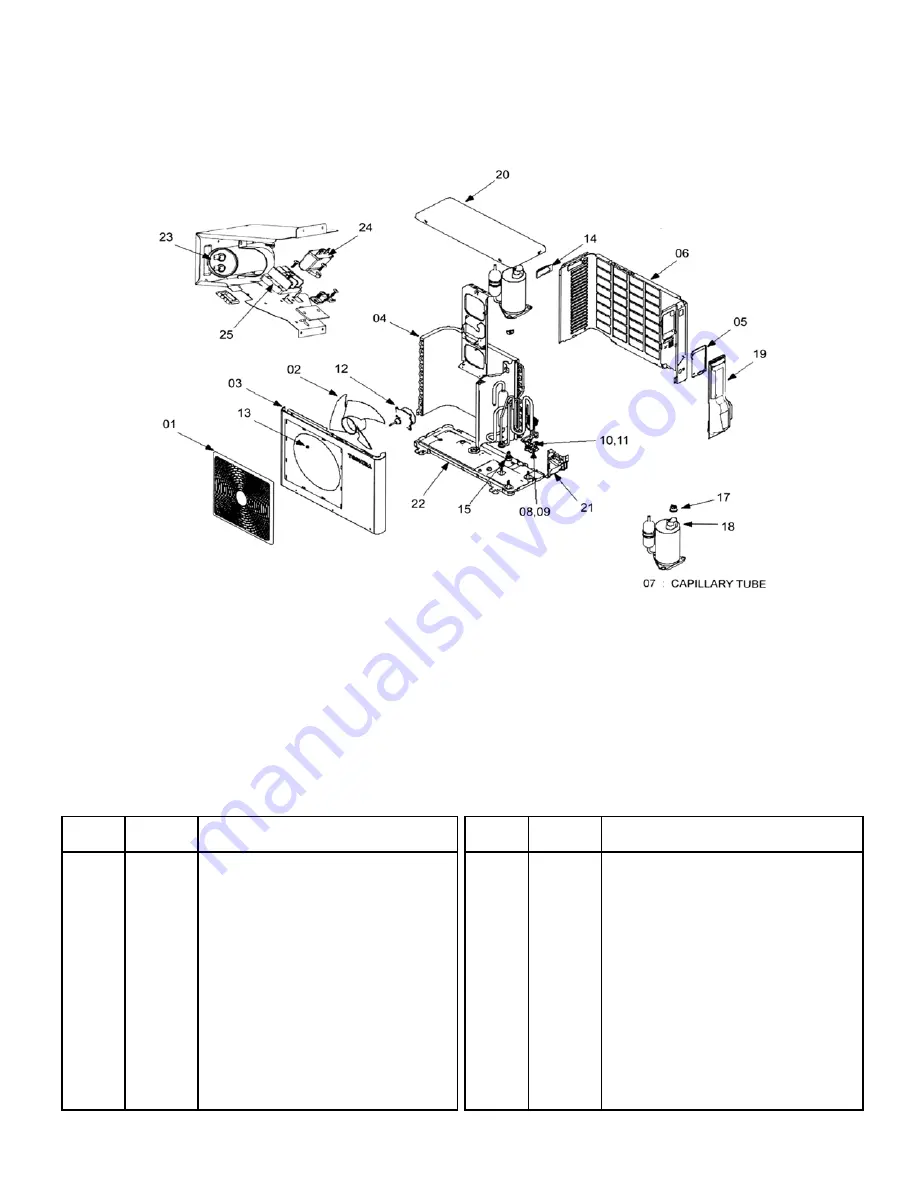

11-

5

. Outdoor Unit (RAS-07

G

A

H

-E)

Location

Part

Location

Part

No.

No.

No.

No.

1

43T19313 FAN GUARD

15

43T49001 CUSHION,RUBBER

2

43T20306 PROPELLER FAN

17

43T54314 RELAY;OVERLOAD

3

43T00398

FRONT CABINET COATING ASSEMBLY

18

43T41365 COMPRESSOR(Made in China)

4

43T43394 CONDENSER ASSEMBLY

19

43T62305 PACKED VALVE COVER

5

43T62309 TERMINAL COVER

20

43T00394 UPPER CABINET COATING ASSEMBLY

6

43T00397 BACK CABINET COATING ASSEMBLY

21

43T63301 FIXING PLATE VALVE

7

43T47308 CAPILLARY TUBE; 1.0 DIA

22

43T42314 BASE COATING ASSEMBLY

8

43T00347 VALVE;PACKED 9.52 DIA

23

43T55338 CAPACITOR,PLASTIC FILM

9

43T47332 BONNET, 9.52 DIA

24

43T55325 CAPACITOR; PLASTIC-FILM

10

43T46308 VALVE;PACKED 6.35 DIA

25

43T60323 TERMINAL-4P

11

43T47331 BONNET, 6.35 DIA

26

43T46321 4 WAY VALVE

12

43T21341 MOTOR;FAN

27

43T49307 SOLINOID COIL

13

43T47001 NUT FLANGE

28

43T79305 DRAIN NIPPLE

14

43T19312 HANDLE

Description

Description