−

35

−

FILE NO. SVM-07023-1

8-4. Indoor Unit

8-4-1. Installation place

•

A place which provides the spaces around the

indoor unit as shown in the above diagram.

•

A place where there is no obstacle near the air inlet

and outlet.

•

A place that allows easy installation of the piping to

the outdoor unit.

•

A place which allows the front panel to be opened.

CAUTION

•

Direct sunlight to the indoor unit’s wireless

receiver should be avoided.

•

The microprocessor in the indoor unit should not

be too close to RF noise sources.

(For details, see the owner’s manual.)

<Remote control>

•

A place where there are no obstacles such as a

curtain that may block the signal from the indoor

unit.

•

Do not install the remote control in a place exposed

to direct sunlight or close to a heating source, such

as a stove.

•

Keep the remote control at least 1 m apart from the

nearest TV set or stereo equipment. (This is

necessary to prevent image disturbances or noise

interference.)

•

The location of the remote control should be

determined as shown below.

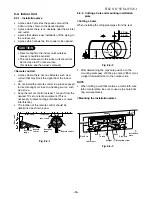

Fig. 8-4-1

75

°

(Top view)

Indoor unit

Reception

range

Reception

range

Remote

control

I

ndoor unit

Remote control

(Side view)

8-4-2. Cutting a hole and mounting installation

plate

<Cutting a hole>

When installing the refrigerant pipes from the rear.

1.

After determining the pipe hole position on the

mounting plate (

A

), drill the pipe hole (

∅

65 mm) at

a slight downward slant to the outdoor side.

NOTE

•

When drilling a wall that contains a metal lath, wire

lath or metal plate, be sure to use a pipe hole brim

ring sold separately.

<Mounting the installation plate>

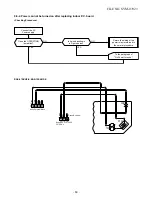

Fig. 8-4-3

35

65

55.5

120

7

Mounting screw

Pipe hole

Pipe hole

Indoor unit

Thread

Weight

Hook

Hook

1

Hook

Installation

plate

Fig. 8-4-2

90 mm

66 mm

65 m

m

42 mm

Pipe hole

45

°

45

°