– 60 –

FILE NO. SVM-02005(1)

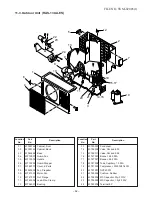

11. EXPLODED VIEWS AND PARTS LIST

11-1. Indoor Unit (E-Parts Assy)

Location

Part

Description

No.

No.

402

43T60002 Terminal Block, 3P

3P AC300V, 20A

403

43T69004 Sensor, Heat Exchanger

10k

Ω

25°C

404

43T69005 Sensor, Thermostat 10k

Ω

25°C

405

43T69079 P.C. Board ASSY, WRS-LED

MCC-861

406

43T60077 Fuse, Temperature, 77°C

Location

Part

Description

No.

No.

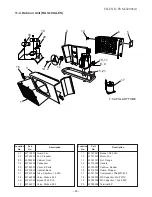

410

43T62003 Cord Clamp

412

43T69076 P.C. Board

(RAS-10UKP-ES)

414

43T69078 P.C. Board

(RAS-13UKP-ES)

416

43T69324 P.C. Board

(RAS-07UKP-ES)

412 10UKP-ES

414 13UKP-ES

416 07UKP-ES

410

403

402

404

406

402

405

410