−

16

−

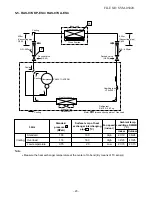

4-3.

Outdoor Unit (RAS-13UA-ES4)

No.

Parts name

Type

Specifications

Output (Rated) 1100W, 2poles, 1 phase, 220

−

240V, 50Hz

1

Compressor

PA150X2C-4FT

Winding resistance (

Ω

)

C-R

C-S

(at 20°C)

2.35

3.22

Output (Rated) 30W, 6poles, 1 phase, 220

−

240V, 50Hz

2

Fan motor (for outdoor)

HF-240-30B or

Winding resistance (

Ω

)

Red-Black

White-Black

(at 20°C)

245 or 237

388.3 or 380

3

Running capacitor

DS451155NPQB

AC 450V, 1.5

µ

F

(for fan motor)

4

Running capacitor

DS441306CPNK

A

C 440V

, 30

µ

F

(for compressor)

4-4.

Outdoor Unit (RAS-10UAH-ES4)

No.

Parts name

Type

Specifications

Output (Rated) 750W , 2poles, 1 phase, 220

−

240V, 50Hz

1

Compressor

PA108X1C-4FZDN

Winding resistance (

Ω

)

C-R

C-S

(at 20°C)

3.75

4.

75

Output (Rated) 30W, 6poles, 1 phase, 220

−

240V, 50Hz

2

Fan motor (for outdoor)

HF-240-30B or

Winding resistance (

Ω

)

Red-Black

White-Black

(at 20°C)

245 or 237

388.3 or 380

3

Running capacitor

DS451155NPQB

AC 450V, 1.5

µ

F

(for fan motor)

4

Running capacitor

DS441256CPNL

A

C 440V

, 25

µ

F

(for compressor)

5

Solenoid coil

(for 4-way valve)

SQ-373

AC 220

−

240V

FILE NO. SVM-05020

WLF-240-30A

WLF-240-30A