FILE NO. SVM-02003

– 37 –

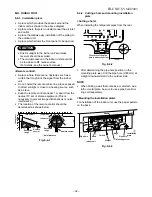

<Left-hand connection with piping>

Bend the connecting pipe so that it is laid within 43 mm

above the wall surface. If the connecting pipe is laid

exceeding 43 mm above the wall surface, the indoor

unit may unstably be set on the wall. When bending the

connecting pipe, make sure to use a spring bender so

as not to crush the pipe.

Bend the connection pipe within a radius of 30 mm.

To connect the pipe after installation of the unit (figure)

Fig. 8-4-19

NOTE

If the pipe is bent incorrectly, the indoor unit may

unstably be set on the wall.

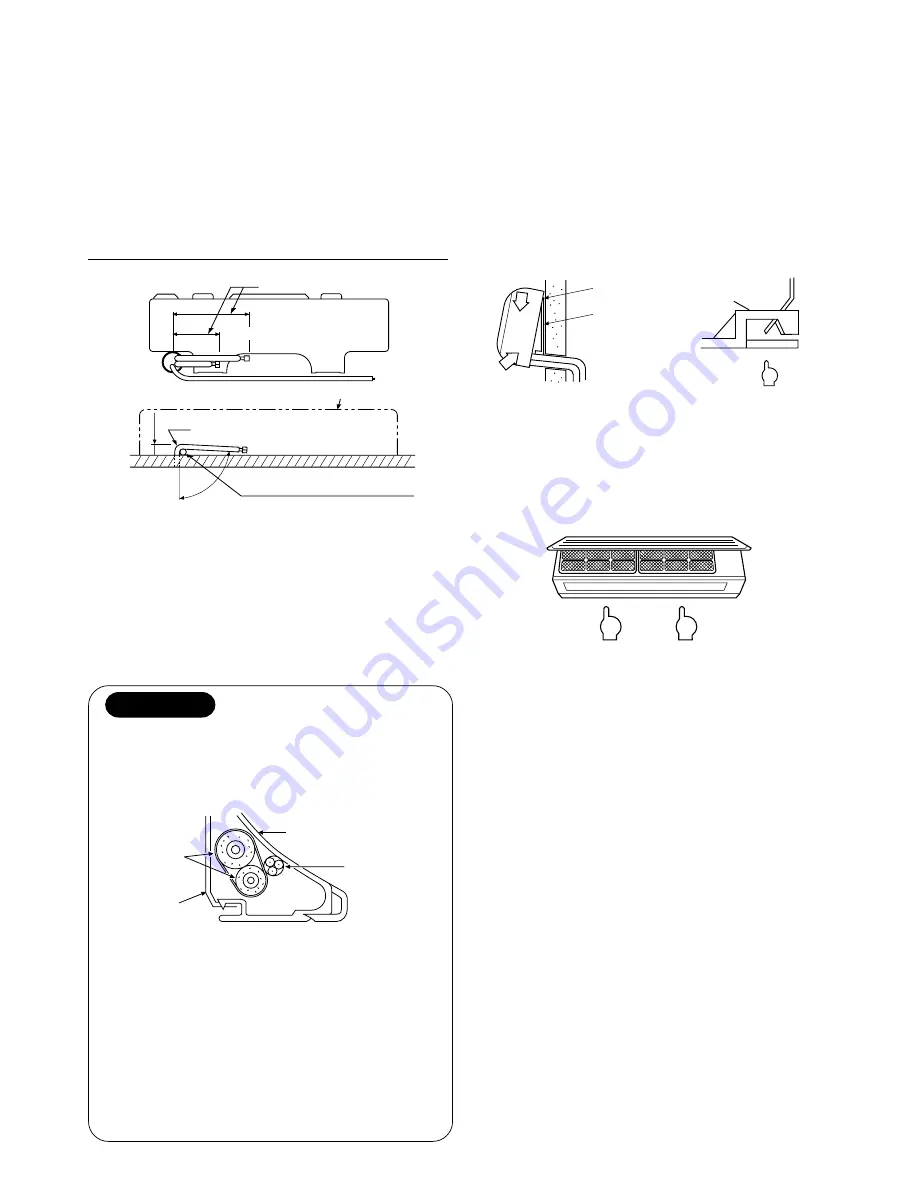

After passing the connecting pipe through the pipe

hole, connect the connecting pipe to the auxiliary pipes

and wrap the facing tape around them.

CAUTION

•

Bind the auxiliary pipes (two) and connecting

cable with facing tape tightly. In case of leftward

piping and rear-leftward piping, bind the auxiliary

pipes (two) only with facing tape.

•

Carefully arrange pipes so that any pipe does not

stick out of the rear plate of the indoor unit.

•

Carefully connect the auxiliary pipes and

connecting pipes to each other and cut off the

insulating tape wound on the connecting pipe to

avoid double-taping at the joint, moreover, seal

the joint with the vinyl tape, etc.

•

Since dewing results in a machine trouble, make

sure to insulate both the connecting pipes. (Use

polyethylene foam as insulating material.)

•

When bending a pipe, carefully do it, not to crush it.

Installation plate

Auxiliary pipes

Indoor unit

Connecting cable

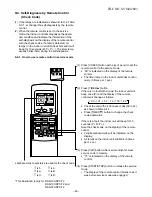

8-4-6. Indoor unit fixing

1. Pass the pipe through the hole in the wall, and hook

the indoor unit on the installation plate at the upper

hooks.

2. Swing the indoor unit to right and left to confirm that

it is firmly hooked up on the installation plate.

3. While pressing the indoor unit onto the wall, hook it

at the lower part on the installation plate. Pull the

indoor unit toward you to confirm that it is firmly

hooked up on the installation plate.

Fig. 8-4-20

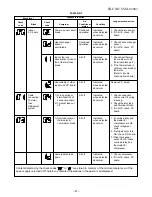

•

For detaching the indoor unit from the installation

plate, pull the indoor unit toward you while pushing

its bottom up at the specified parts.

Fig. 8-4-21

Press

(unhook)

Hook

1

Installation

plate

Hook here

1

2

Push

Push

80

°

270 mm

170 mm

43 mm

(To the forefront of flare)

Liquid side

Outward form of indoor unit

R 30 mm (Use polisin (polyethylene

core or the like for bending pipe.)

Use the handle of screwdriver, etc.

Gas side