12

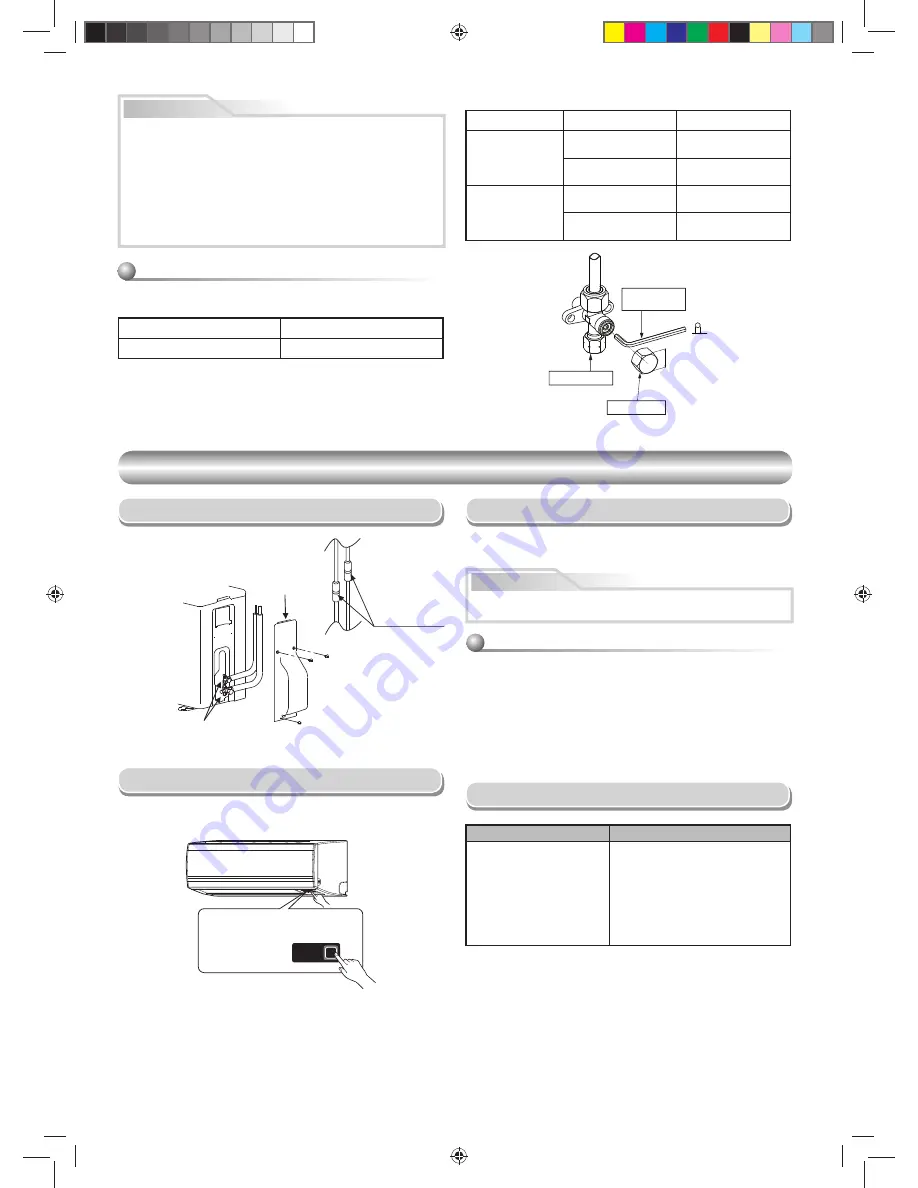

Packed valve handling precautions

• Open the valve stem all the way out, but do not try to open it beyond the

stopper.

• Securely tighten the valve cap with torque in the following table:

Pipe size of Packed Valve

Size of Hexagon wrench

1/2 in. (12.7 mm and smallers)

A = 3/16 in. (4 mm)

Cap

Cap Size (H)

Torque

Valve Rod Cap

43/64 in. - 3/4 in.

(H17 - H19)

10 to 13 Ibf.ft

(14~18 N·m)

55/64 in. - 1-3/16 in.

(H22 - H30)

24 to 31 Ibf.ft

(33~42 N·m)

Service Port Cap

35/64 in.

(H14)

37 to 46 Ibf.ft

(50~62 N·m)

43/64 in.

(H17)

10 to 13 Ibf.ft

(14~18 N·m)

A

H

Hexagon wrench

is required.

Service Port Cap

Valve Rod Cap

OTHER

OTHER

Gas Leak Test

Test Operation

Troubleshooting (Check Point)

To switch the TEST RUN (COOL) mode, press RESET button for 10 seconds.

(The beeper will make a short beep.)

Auto Restart Setting

The product was shipped with Auto Restart function in the ON position.

Turn it OFF if this function is not required.

How to cancel the Auto Restart

Check

fl

are nut

connections for gas

leak with a gas leak

detector or soap

water.

This product is designed so that after a power failure it can restart

automatically in the same operating mode as before the power failure.

1. Press and hold the RESET button on the indoor unit for 3 seconds to

cancel the operation. (3 beeps will sound but OPERATION lamp does not

blink)

2. Press and hold the RESET button on the indoor unit for 3 seconds to set

the operation. (3 beeps will sound and OPERATION lamp blink 5 time/

sec for 5 seconds)

• Do not operate ON timer and OFF timer.

Note :

Default setting of auto restart operation is ON.

Check places with

fl

are nut connections

(indoor unit)

Check places for

outdoor unit.

Valve cover

Information

RESET

RESET button

CAUTION

•

5 IMPORTANT POINTS FOR PIPING WORK.

(1) Take away dust and moisture (inside of the connecting pipes).

(2) Tighten the connections (between pipes and unit).

(3) Evacuate the air in the connecting pipes using a VACUUM PUMP.

(4) Check gas leak (connected points).

(5) Be sure to fully open the packed valves before operation.

•

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Never use the system compressor as a vacuum pump.

The unit does not operate.

Cooling or Heating is abnormally low.

• The power main switch is

turned off.

• The circuit breaker is tripped.

• ON timer is set.

• The

fi

lters are blocked with dust.

• The temperature has been set

improperly.

• Windows or doors are open.

• The air inlet or outlet of the outdoor

unit is blocked.

• The fan speed is too low.

• The operation mode is FAN or DRY.

1110651824-2 EN.indd 12

1110651824-2 EN.indd 12

12/13/13 4:58 PM

12/13/13 4:58 PM

Summary of Contents for RAS-09 12EA Series

Page 39: ...1110251291 2 FR indd 13 1110251291 2 FR indd 13 12 17 13 5 03 PM 12 17 13 5 03 PM ...

Page 40: ...1110251291 2 FR indd 14 1110251291 2 FR indd 14 12 17 13 5 03 PM 12 17 13 5 03 PM ...

Page 79: ...1110651824 2 FR indd 13 1110651824 2 FR indd 13 12 17 13 2 15 PM 12 17 13 2 15 PM ...

Page 80: ...1110651824 2 FR indd 14 1110651824 2 FR indd 14 12 17 13 2 15 PM 12 17 13 2 15 PM ...