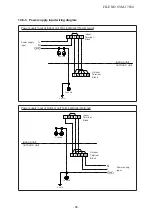

10-5-1. Wiring Connection

10-5. Electrical works

Outdoor unit

Fig. 10-

5

-

1

Fig. 10-

5

-

2

The power supply can be selected to connect to indoor unit or outdoor unit. Choose proper way and connect

the power supply and connecting cable by follow the instruction as following.

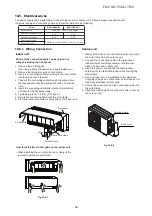

How to install the air inlet grille on the indoor unit

• When attaching the air inlet grille, the contrary of the

removed operation is performed.

Indoor unit

Wiring of the connecting cable can be carried out

without removing the front panel.

1.

Remove the air inlet grille.

Open the air inlet grille upward and pull it toward you.

2.

Remove the terminal cover and cord clamp.

3.

Insert the connecting cable (according to the local cords)

into the pipe hole on the wall.

4.

Take out the connecting cable through the cable slot on

the rear panel so that it protrudes about 20 cm from the

front.

5.

Insert the connecting cable fully into the terminal block

and secure it tightly with screws.

6.

Tightening torque : 1.2 N·m (0.12 kgf·m)

7.

Secure the connecting cable with the cord clamp.

8.

Fix the terminal cover and air inlet grille on the indoor unit.

Cord clamp

Terminal cover

Screw

Screws

Air inlet grille

Front panel

Valve cover

Terminals block

1.

Remove the valve cover, the electric parts cover and

the cord clamp from the outdoor unit.

2.

Connect the connecting cable to the terminal as

identif ed by the matching numbers on the terminal

block of indoor and outdoor unit.

3.

Insert the power cord and the connecting cable

carefully into the terminal block and secure it tightly

with screws.

4.

Use vinyl tape, etc. to insulate the cords which are

not going to be used. Locate them so that they do not

touch any electrical or metal parts.

5.

Secure the power cord and the connecting cable with

the cord clamp.

6.

Attach the electric parts cover and the valve cover on

the outdoor unit.

Model

RAS-

10

BKV-

E

1

RAS-

13

BKV-

E

1

Power source

50Hz, 220 – 240 V Single phase

Maximum running current

6.7

A

7.

1

A

Circuit breaker rating

8

.5A

9.0

A

Power supply cable

H07RN-F or 60245 IEC66 (1.5 mm

2

or more)

Connecting cable

FILE NO. SVM-17030

- 56 -