Summary of Contents for RAS-10N3ACV Series

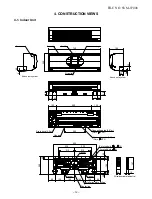

Page 16: ...FILE NO SVM 07008 15 4 2 Outdoor Unit C L C L ...

Page 17: ... 16 FILE NO SVM 07008 5 WIRING DIAGRAM 5 1 Indoor Unit ...

Page 18: ...FILE NO SVM 07008 17 5 2 Outdoor Unit ...

Page 83: ...FILE NO SVM 07008 82 P C board layout Solder side ...

Page 94: ...FILE NO SVM 03008 87 TOSHIBA CARRIER CORPORATION ...