– 34 –

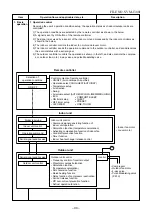

Item

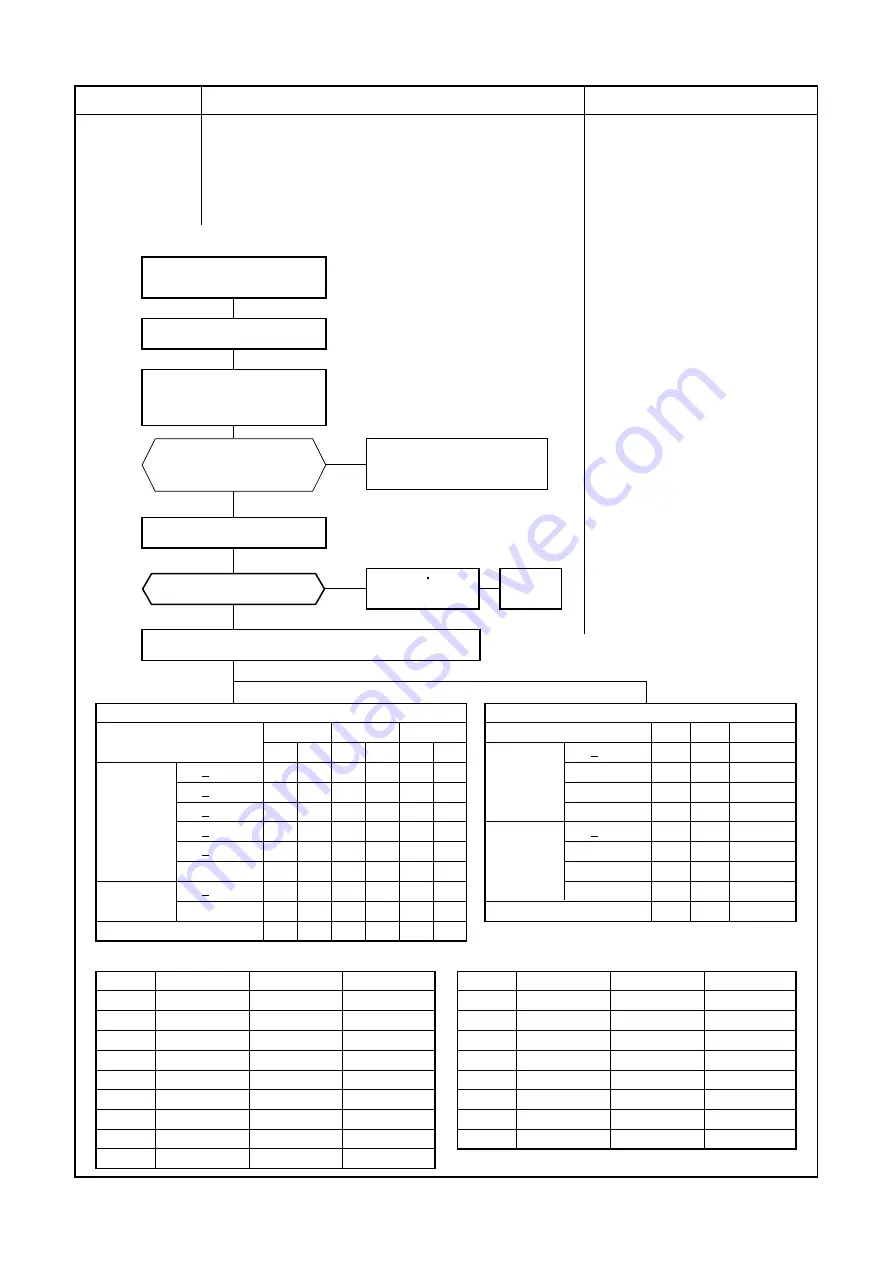

3. Outdoor fan

motor control

Operation flow and applicable data, etc.

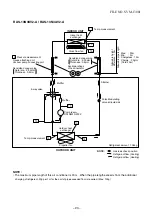

The blowing air volume at the outdoor unit side is controlled.

Receiving the operation command from the controller of

indoor unit, the controller of outdoor unit controls fan speed.

* For the fan motor, a DC motor with non-stage variable

speed system is used. However, it is limited to 8 stages for

reasons of controlling.

Description

1) The operation command sent

from the remote controller is

processed by the indoor unit

controller and transferred to the

controller of the outdoor unit.

2) When strong wind blows at

outdoor side, the operation of air

conditioner continues with the

fan motor stopped.

3) Whether the fan is locked or not

is detected, and the operation of

air conditioner stops and an

alarm is displayed if the fan is

locked.

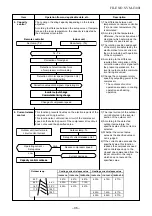

4) According to each operation

mode, by the conditions of

outdoor temperature (To) and

compressor revolution, the speed

of the outdoor fan shown in the

table is selected.

Compressor speed (rps)

To

> 38°C

To > 28°C

To

To > 15°C

To > 5.5°C

To > 0°C

During

To > 38°C

ECO mode

To < 38°C

When To is abnormal

~ 13.8

~ 31.7

32.3 ~ MAX

MIN MAX MIN MAX MIN MAX

f 2

f 3

f A

f C

f D

f F

f 2

f 3

f 7

f A

f 9

f C

f 1

f 3

f 2

f 5

f 4

f 7

f 1

f 1

f 1

f 2

f 2

f 4

f 2

f 3

f B

f C

f C

f D

In cooling operation

Compressor speed (rps)

To > 15°C

To

To < 15°C

To < 5.5°C

To <

−

5.0°C

To > 15°C

During To < 15°C

ECO mode

To < 5.5°C

To <

−

5.5°C

When To is abnormal

~16.8 ~47.9 48.5 ~ MAX

f 3

f 8

f 9

f 3

f 9

f A

f 8

f A

f D

f B

f C

f D

f 3

f 3

f 6

f 3

f 3

f 8

f 5

f 9

f 9

f 7

f A

f B

f A

f B

f D

In Heating operation

f 2

f 3

f C

f D

f E

f F

To

<

0°C f 0 f 0 f 0 f 1 f 1 f 2

f D

f F

f D

f F

f F

f 2

f 3

f 2

f 3

f B

f C

f D

FILE NO. SVM-13001

Air conditioner ON

(Remote controller)

YES

YES

NO

NO

Indoor unit controller

Fan motor ON

3) Fan lock

4) Motor operates as shown in the table below.

1) Outdoor unit

operation

command

(Outdoor

fan

control)

Air conditioner

OFF

Alarm

display

2) Fan speed

≥

400.

(by strong wind)

when the motor OFF.

Fan motor OFF continues

(Use wind for heat

exchanging)

Outdoor fan speed (rpm)

Ta

13

N3AV2-A

p

16

N3AV2-A

f 1

f 2

f 3

f 4

f 5

f 6

f 7

f 8

10

N3AV2-A

200

200

200

300

300

300

370

370

370

440

440

440

440

440

440

500

500

500

550

550

550

600

600

600

Tap

f 9

f A

f B

f C

f D

f E

f F

600 650 650

600 700 700

650 700 700

700

800

800

700 8

5

0 8

5

0

700 8

5

0 8

5

0

700 8

5

0

85

0

f 0

0

0

0

13

N3AV2-A

16

N3AV2-A

10

N3AV2-A